INTERTANKO依据IMO脱碳法规更新船舶能效计划进展汇报(译)

作者:Wong Kai Cheong INTERTANKO高级技术经理

介绍

国际独立油轮船东协会(INTERTANKO)是一个会员经营、直接进入的贸易组织,自1970年以来一直为独立油轮船东发声。它代表全球大多数独立油轮船东和相关方的利益。会员遍布国家、区域和国际层面。INTERTANKO在中国和整个亚洲的油轮船东会员占INTERTANKO总吨位的很大一部分。而INTERTANKO在新加坡设立分支机构已超过十年。

INTERTANKO积极致力于为会员之间交换意见提供场所,加强技术和商业之间的交流。定期组织会员和其他行业利益相关者交流油轮行业新信息和最佳运营实践。借INTERTANKO在国际海事组织(IMO)、联合国贸易和发展会议(UNCTAD)和国际油污赔偿基金(IOPC)的观察员地位,INTERTANKO的会员一直在战略性地影响着行业发展的重要方面。

INTERTANKO会员公开表明他们对海运完全脱碳的承诺,为了兑现承诺,INTERTANKO一直在积极寻求并鼓励所有相关方开发新技术,采用新能源共同实现这一目标。同时要感谢森海海事提供机会分享一些组织目前脱碳的新进展,主要包括现有船舶能效指数(EEXI)和碳排放强度指数(CII)两个方面。

国际海事组织温室气体(GHG)战略是继《巴黎协定》之后应对气候变化的积极响应。当前全球范围正在经历越来越多的极端天气事件,这也提醒着我们要立即采取行动应对气候变化。IMO设定的目标是,与2008年的基准值相比,国际航运业到2030年实现碳排放量减少40%,到2050年减少70%。所有相关方必须共同努力,逐步提升能源使用效率,减少排放以实现这些减排目标。

EEXI & CII

船舶能效指数和碳强度指数都将对现有船舶产生影响。是IMO为实现2030年目标而重点关注的两项指标。从2023年1月1日起,5,000 GT及以上的船舶必须具备经过验证和批准的船舶能效管理计划 (SEEMP) 第 III 部分,以记录其船舶如何在未来三年内实现其CII目标,由MARPOL附则VI强制要求,于2022年10月1日生效,自2023年1月1日起强制实施。

EEXI可以看作是一种“设计措施”;即EEXI公式是衡量船舶“建造”效率的指标,而不是它在现实航行中的表现。船舶应满足EEXI要求,因其限制了标准条件下每吨英里的二氧化碳排放量,要求值设定为比每种特定船型的能效设计指数 (EEDI)基准值低20%或30%。计算船舶达到的EEXI值,然后通过降低推进功率进行调整以满足要求的EEXI值,从而使燃料消耗和每吨英里的二氧化碳排放量等于或低于要求值。计算和获得的EEXI必须连同申请,验证所需信息和任何其他相关的技术文件一起提交以供验证。

EEXI技术文件应包含船舶载重、主辅机额定装机功率(MCR)、安装可超越轴/发动机功率限制系统时的限制装机功率,以及船舶用于计算的参考速度等信息。如果安装了可替代的轴/发动机功率限制系统,验证者应确认该系统已正确安装、并按照EEXI要求密封、且使用了备用电源,船舶具备经过验证的船舶管理手册(OMM)。除非船舶进行了影响推进功率的修改,而影响了船舶的原始EEXI,否则验证只需一次达成符合即可。

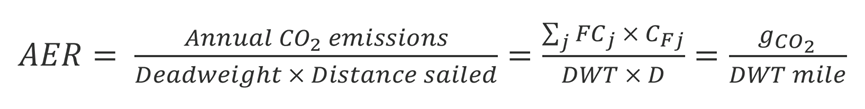

不同于EEXI是一种设计措施,CII 是一种“运营措施”,它规定了每吨英里 CO2 的排放值,从而对船舶的运营效率进行评价。但是,该规定没有考虑船舶海上贸易航行复杂性。即使两艘建造相同,管理相同的船,在完成不同运输任务和不同环境下的碳排放量也可能不同。根据船舶的总排放量和一年中行驶的距离,船舶的CII等级分为A、B、C、D和E。等级有年度排放率(AER)与基准比较得出。

燃料方面,使用的燃料量越少,船舶的CII等级越低,船舶行驶距离越远,CII等级越高。如果船舶连续三年获得CII等级“D”或获得一次“E”等级,则船舶必须提出整改计划,否则将不会给该船舶签发合规声明。AER 计算公式如下:

SEEMP

为满足CII规定,船舶必须配备SEEMP。合规的SEEMP有三个部分:

1. SEEMP要求随着时间的推移监测船舶和船队的效能。应有提高船舶能效和减少碳排放的方法。

2. SEEMP描述了用于收集“IMO船舶燃油消耗数据收集报告”所要求的数据收集报告方法。

3. SEEMP涉及船舶的CII计算,例如用于计算船舶达到年度运营CII的方法。为了有效实施这些部分,必须让船上船员了解SEEMP中的能效措施,并安排进行适当的培训,使船员能有效遵守和执行这些措施。

SEEMP Part I

为满足新要求,SEEMP第I部分将成为协助公司管理船舶效能的工具。对于根据ISO要求建立环境管理体系(EMS)的船舶,可能该体系已经涵盖SEEMP第I部分的要求,或SEEMP 第 I 部分已经是船舶安全管理计划的一部分。

第一部分细分为——规划、实施、监控和自我评估与改进;在这样的闭环下,SEEMP第I部分将有助于使船舶持续改进。

在规划阶段,根据船舶的运营情况,可以选择多种方式提高能源效率,例如速度优化、及时考虑泊位可用性和到达时间、天气路线、船体维护、改装,能源效率设备和替代燃料的使用等方面。目标设定应使用各种可量化的指标,包括年燃料消耗量、AER和其他碳强度指标。CII预计将成为一个较为普遍的目标管理指标。

公司积极参与并对船员提供支持有助于实现特定措施。公司层面可以联合承租人、货主、燃料供应商、港口和交通管理等共同协调和解决减排目标上的冲突。同时还可以为船员安排相关培训。此外,建立记录保存制度有助于监测目标实施进度,有利于定期审查和评估。如船舶偏离其能效计划措施,尤其是超出船员控制范围的因素引起的(例如,长时间等待泊位、拥堵、恶劣天气)情况,应深挖其根本原因。

优化航行计划将有助于船员更好的执行能效计划,船舶可以选用现有的航行计划制定软件。如前所述,行驶距离越长,CII等级越高,因此,在为航次选择最佳速度时,应获取目的港的泊位和引航员安排等信息。如果需要对到达时间进行调整,这还需要与目的港进行及时沟通。优质的导航系统可以减少偏离,从而节省燃料,通过较少的频率和较小的修正来更好地控制航向,减少由于方向舵阻力造成的燃料损耗,船舶自动驾驶也具有这样的优势。

“最佳速度”还取决于功率/消耗曲线、船舶的速度/轴功率曲线和船舶的螺旋桨特性,通常会在螺旋桨曲线上描绘出不同转速下的推力。与发动机扭矩和转速相关的最佳发动机轴转速(以RPM为单位)的信息通常由发动机制造商提供,并允许船舶运营商确定发动机是否在其限制范围内运行。恒定转速通常比不断调整发动机功率/速度更有效,因此一些船舶配备了自动发动机管理系统。然而,发动机制造商和造船厂的建议是基于发动机处于最佳状态时的理想条件,因此船员必须时刻注意是否有迹象表明发动机和其他机械没有正常高效运转,以便船员和公司能够确定维护、螺旋桨/船体清洁等的需求,并做出相应的计划。

纵倾和吃水等静压参数对阻力或水阻力以及转向特性有显着影响,并影响船舶实现航行速度目标所需的发动机功率。对于任何给定的吃水,都有一个提供最小阻力的纵倾条件。理想情况下,应在整个航程中不断评估最佳纵倾条件,并进行任何相应的压载调整,尽管设计或安全因素可能会妨碍纵倾优化的充分利用,但可根据需要对压载物进行调整,同时考虑到满足最佳配平和转向条件的要求。在做货物计划时,高级船员应通过良好的货物计划努力达到最佳压载条件。

SEEMP Part II

SEEMP第II部分要求船舶制定数据收集计划,以列出船上所有燃油(以及每种燃油的消耗方式)的方法。这包括主机、辅机、燃气轮机、锅炉和惰性气体发生器消耗的能量。无论船舶是否在航,都必须记录消耗的数量,收集方法主要是使用交付给船舶的每种燃料油的燃油交货单(BDN)。BDN必须在燃油交付后保留在船上三年。另一种选择是使用流量计来测量所有日常燃油消耗量。如果流量计发生故障,应制定应急计划,方法是使用手动储罐读数或其他方式。如果流量计用作SEEMP的一部分,则应指定流量计的校准时间表,并在船上提供校准和维护记录。使用LNG货物作为燃料的LNG运输船将使用贸易交接监测系统来监测/记录罐内的货物量。减去LNG燃料中的氮质量含量,因为氮不会导致CO2排放。

船舶行驶的距离必须提交给其船旗国主管部门,并且SEEMP II部分应规定记录行驶距离的方法。根据SOLAS第28条,如果自动报告系统包括其传输的记录功能,并且这些功能和与定位设备的接口由船长定期验证,则可以使用这些系统。必须记录船舶在自身推进下航行的时间并提交给船旗国管理局。

SEEMP Part III

SEEMP第III部分要求描述用于计算船舶达到的年度运营CII的方法,以及将该值报告给船旗国主管部门的过程。船舶未来三年每年的CII年度运营值必须参考IMO 2022 CII指南G2 MEPC.353(78),IMO 2022 CII等级指南G4(MEPEC.354(78)),以及IMO 2022 CII减少系数指南G3 (MEPC.338(76))。船舶必须达到最低等级“C”——依据船舶载重吨对应CII中间参考线上的值。这代表30%的船舶CII在2019年达到该船型的CII要求。每年的船舶年度CII等级必须达到“C”或以上(即“B”或“A”)。

如果船舶连续三年被评为“D”级或一年被评为“E”级,则必须制定一套纠正措施,使船舶在随后的自然年检中至少达到“C”级。措施中应涵盖要采取的额外措施、实施时间以及对船舶CII等级的预期影响。应指定公司人员负责在整个过程中监控和审查纠正措施的有效性。同时,也要确定影响纠正措施有效性的因素。

降速航行

如上所述,为满足EEXI/CII要求,许多现有船舶预计将减少发动机载荷作为其主要减排措施,这样不需要或很少需要对船舶进行改建,然而,这意味着现有船舶将可能偏离其最初设计的参数运行,大多数船舶能够调整操作或设备设置以适应慢速航行,不会出现重大问题。尽管船舶进行了十多年的慢航并取得了不错的效果,但也存在一些无法避免的问题。轮机员将面临较大压力,机舱工作量会增加,因为他们要处理诸如涡轮增压器结垢增加和排气系统中可能发生烟灰火灾等问题。预计燃油喷射器和活塞环中的碳沉积物也会增加。由排气系统污染引起的机舱火灾此前时有发生,其中一些是灾难性的,导致生命、船舶和货物的损失,因此需要提高对低负荷运行时与烟灰积聚相关的火灾风险的培训和应对。

更令人担忧的是,船员是否可以轻松安全地让降速的船舶提速,船舶是否安装有主机功率限制器(EPL) 或轴功率限制器(SHAPoLi),以应对在恶劣天气下航行的需要。为了让船员熟悉EPL/SHaPoLi系统的安全程序,发动机制造商和其他专家可能需要提供相关信息并提供简单安全的方法来达到航行所需的船舶动力要求。船员必须接受适当的培训并定期进行演习,以便为此类情况做好准备。此外,当发动机或其他机械在需要时突然进入更高功率模式时,在长时间低负载或低速条件下运行的机械部件可能容易发生故障。在部署最大功率之前,必须执行某些预防措施和例行程序。

执行节点

预计在2023年1月1日之前生效的EEXI和CII法规的各个执行节点是所有船舶运营商和船员关心的方面。船舶的SEEMP应通过初步验证提交船旗国或其认可组织,以便在2022年12月31日之前得到船舶合规确认。船舶随后需要2023年的CII报告进行数据收集,这是实施SEEMP的第一年。2023年CII数据必须在2024年3月31日之前提交以供验证。每艘船的CII等级将得到验证,并附合规声明。如果不需要为实施和验证制定纠正行动计划,则在下一年重复该流程。

INTERTANKO update on the

implementation of revised ship energy efficiency plans to meet IMO decarbonisation regulations(原文)

Wong Kai Cheong, KC Wong

Senior Technical Manager

INTERTANKO

Introduction

The International Association of Independent Tanker Owners (INTERTANKO) is a Member-run, direct entry, trade organisation that has served as the voice for independent tanker owners since 1970. It represents the majority of independent tanker owners and operators worldwide to further the interests of its Members at national, regional and international levels. INTERTANKO’s Membership in China, and Asia at large, operates a substantial percentage of the overall INTERTANKO tonnage, and INTERTANKO has had a branch office in Singapore for well over a decade.

INTERTANKO actively works on a wide range of operational, technical, legal and commercial issues affecting tanker owners and operators around the world. It draws on regular and direct contact with its Members and other industry stakeholders to develop and disseminate information and best practice, essential to the tanker industry. Through INTERTANKO observer status at the International Maritime Organization (IMO), the United Nations Conference on Trade and Development (UNCTAD) and the International Oil Pollution Compensation Funds (IOPC), INTERTANKO's Members have been strategically influencing important developments at the highest level.

INTERTANKO Members have continually and openly stated their commitment to the total decarbonisation of seaborne transportation. In reaching this decision, INTERTANKO has been actively pursuing and encouraging the participation of all stakeholders in the development of the technologies and fuels needed for international shipping to meet this goal safely. We would like to thank Singhai Marine Services for this opportunity to share information on some key decarbonisation developments, namely the Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Indicator (CII)

One outcome from the IMO's greenhouse gas (GHG) strategy has been a positive response to mounting pressure for action to address climate change following the Paris Agreement. As seen and experienced by all of us, reports of extreme, and sometimes violent, weather incidents have become more commonplace – hence the need for immediate action. The target set by IMO is for international shipping to implement a 40% reduction in carbon emissions by 2030, and a 70% reduction by 2050, compared to a baseline value from 2008. All stakeholders, including those on board, must work together in order for these reductions to take place through the various energy efficiency and emissions requirements that will become stricter over time.

EEXI & CII

EEXI and CII, which will each have an impact on existing ships, are the two main IMO regulations detailing the short-term measures to help meet the targets set by IMO for 2030. From 1 January 2023, ships of 5,000 GT and above must have onboard a verified and approved Ship Energy Efficiency Management Plan (SEEMP) Part III to document how their ship plans to achieve its CII targets over the next three years. These new regulations will be mandatory under MARPOL Annex VI and come into force on 1 October 2022, but are applicable from 1 January 2023.

EEXI can be seen as a "design measure"; i.e. the EEXI formula is a measure of how efficient the ship is ‘as built’, not how it performs at sea in the real world. Ships shall meet a required EEXI value limiting the amount of CO2 emissions per ton-mile in standard operating conditions, with the required value set at 20% or 30% lower than the Energy Efficiency Design Index (EEDI) baseline values for each particular ship type. A ship’s attained EEXI value is calculated, then, adjusted to meet the required EEXI value through a reduction in propulsion power in order for fuel consumption, and thus CO2 emissions per ton-mile, to be equal to or lower than the required value. The calculated, attained EEXI must be submitted for verification together with an application for a survey and an EEXI Technical File containing the necessary information for verification and any other relevant background documents.

The EEXI Technical File shall contain information including the ship's deadweight, rated installed power (MCR) of the main and auxiliary engines, the limited installed power in cases where an overridable Shaft/Engine Power Limitation system is installed, plus the ship's reference speed for calculating its EEXI. In cases where an overridable Shaft/Engine Power Limitation system is in place, the verifier should confirm that the system is appropriately installed, sealed in accordance with EEXI requirements, has the use of a reserve power source, and that a verified Onboard Management Manual (OMM) is on board. Compliance with EEXI is required only once, unless the ship later has modifications that impact propulsion power and thus the ship’s original EEXI.

Where EEXI was a design measure, CII is an "operational measure" that imposes those set values of CO2 emissions per ton-mile that led to the rating of the ship’s operational efficiency. Unfortunately, this regulation does not take into account the complexity of operational conditions experienced by trade at sea. Even if two ships are identical and operated under the same management, their carbon emissions may be different due to the ships being operated under different contractual and environmental conditions. A ship will be given a CII rating of A, B, C, D or E, depending on its total emissions and the distance travelled in a year. An Annual Emission Ratio (AER)will be calculated and compared against a benchmark to determine the CII rating.

Fuel-wise, the lower the amount of fuel used, the lower the CII rating for the ship, while for distance, the farther a ship travels the better the CII rating. If the ship gets a CII rating of ‘D’ for three consecutive years or an ‘E’ rating for just one year, the ship must come up with a correction plan or there will be no Statement of Compliance issued. The formula for AER is as follows:

SEEMP

To meet the CII regulations, ships must have a SEEMP on board. The mandated SEEMP is structured into three parts:

· SEEMP Part I requires the monitoring of ship and fleet efficiency performance over time. Ways of improving a ship's energy efficiency performance and carbon intensity shall be included.

· Part II of the SEEMP includes the description of the methodologies used to collect data required under the ‘IMO Data Collection Requirements for collection and reporting of ship fuel oil consumption data’.

· The new Part III of the SEEMP relates to a ship’s CII, such as the methodology used to calculate the ship’s attained annual operational CII. For these parts to be effectively implemented, shipboard crew must be made aware of the energy efficiency measures as detailed in the SEEMP and appropriate training arranged and conducted to enable crew to carry out said measures.

SEEMP Part I

To meet the new requirements, SEEMP Part I should be a management tool to assist a company in managing the energy efficiency performance of the ship. The SEEMP Part I may already exist for ships that have an environmental management system (EMS) in place under ISO 14001, or it may already be part of the ship's safety management plan.

Part I contains four components – Planning, Implementation, Monitoring and Self-Evaluation and Improvement; under this "plan-do-check-act" cycle loop, it is expected that continuous revision of SEEMP Part I will help enable the ship to improve on an ongoing basis.

During the planning stage, based on the ship's operational profile, there will be a variety of options that could improve energy efficiency, such as speed optimisation, just-in-time considerations on berth availability and arrival timings, weather routeing, hull maintenance, retrofitting of energy efficiency devices and use of alternative fuels, among other things. Goal setting shall be carried out using various quantifiable indicators, which could include annual fuel consumption, AER, and other carbon intensity indicators. CII is expected to be a commonly chosen goal-setting indicator.

The company's involvement and support to the crew is vital for certain measures to materialise. Many stakeholders, including charterers, cargo owners, fuel suppliers and ports and traffic management services, need to be approached at company level for the coordination and resolution of any conflicting objectives among said stakeholders. The crew are also dependent on the company for filling any gaps in knowledge and to arrange for any training. Setting up a record-keeping system is helpful for monitoring the progress of implementation and for the periodic review and evaluation in this regard. Events or occurrences that cause the ship to deviate from its energy efficiency planned measures, especially those occasions when operational conditions (e.g. prolonged waiting time for berths, congestion, severe adverse weather) are outside the control of the ship's crew, should be documented along with the reasons behind them.

Considering fuel-efficiency operations that the crew are expected to carry out, improved voyage planning would be one of the easiest to achieve. There are commercially available software tools for voyage planning and weather routing that can easily be put on board. As mentioned previously, the longer the distance travelled, the better the CII rating, hence, when selecting the optimal speed for the voyage, information such as berth and pilot availability timing at the destination port should be obtained. This would also require early and regular communication with the destination port if adjustments on arrival timings need to be made. An integrated Navigation and Command System can achieve significant fuel savings by simply reducing the distance sailed "off track". The principle is simple: better course control through less frequent and smaller corrections will minimise losses due to rudder resistance. Retrofitting of a more effective autopilot to existing ships could also be considered.

‘Optimal speed’ is also dependent on the power/consumption curve, the ship’s speed/shaft power curve and the ship's propeller characteristics, which would usually be depicted on the propeller curve showing the thrust at various rotational speeds. Information on optimal engine shaft speed, in RPM, in relation to the engine torque and speed would generally be provided by the engine manufacturer and will allow the ship operator to establish whether the engine is being operated within its limits. A constant shaft RPM is generally more efficient than continually adjusting engine power/speed, and some ships are fitted with automated engine management systems for this reason. However, engine maker and shipbuilder recommendations are based on ideal conditions when the engine is in prime condition, so it is essential for the crew to be constantly on the lookout for tell-tale signs that give an indication that the engine and other machinery are not quite operating at maximum efficiency. This will allow the crew and the company to identify the need for maintenance, propeller/hull cleaning etc, and plan accordingly.

Hydrostatic parameters such as trim and draft have significant effects on drag, or water resistance, as well as steering characteristics, and have an impact on the amount of engine power required for the ship to achieve voyage speed targets. For any given draft there is a trim condition that offers minimum resistance. Ideally, the optimum trim conditions should be assessed continually throughout the voyage as trim changes due to the depletion of consumables such as fuel, and any corresponding ballast adjustments, are made, although design or safety factors may preclude full use of trim optimisation. Ballast should also be adjusted as needed, taking into consideration the requirements to meet optimum trim and steering conditions. During cargo planning, officers should try to achieve optimum ballast conditions through good cargo planning.

SEEMP Part II

The SEEMP Part II requires the ship to have a Data Collection Plan to set out the methodology by which all fuel oil (and how each type of fuel oil) is consumed on board. This includes that consumed by the main engines, auxiliary engines, gas turbines, boilers and inert gas generator. The quantity consumed must be recorded regardless of whether the ship is underway or not and methods for collection would predominantly be using bunker delivery notes (BDNs) ffor each type of fuel oil delivered to the ship. BDNs must be retained on board for three years after the fuel oil has been delivered. Another alternative is to use flow meters to keep measurements of all daily fuel oil consumption. A contingency plan should be developed in the event of flow meter malfunction, by either using manual tank readings or other means. If flow meters are used as part of the SEEMP, the calibration schedule of the meters should be specified and the calibration and maintenance records made available on board. LNG carriers that use LNG cargo as fuel would use the Custody Transfer Monitoring System to monitor/record the cargo volumes inside the tanks. Nitrogen mass content in LNG fuel is subtracted as nitrogen does not contribute to CO2 emissions.

The distance travelled by the ship must be submitted to its Flag Administration and the SEEMP Part II should specify the method by which distance travelled is recorded. As per SOLAS Regulation 28, automated reporting systems may be used if they include a recording function of their transmission, and that those functions and interfaces with position-fixing equipment are subjected to regular verification by the ship's master. The hours the ship was underway under its own propulsion must be recorded and submitted to the Flag Administration.

SEEMP Part III

SEEMP Part III requires a description of the methodology used to calculate the ship's attained annual operational CII, and the processes to report this value to the ship's Flag Administration. The required annual operation CII values for the ship for each of the next three years must be calculated according to IMO 2022 CII Guidelines G2 (MEPC.353(78)), IMO 2022 CII rating Guidelines G4 (MEPEC.354(78)) and the IMO 2022 CII reduction factors guidelines G3 (MEPC.338(76)). The ship must attain a minimum rating of ‘C’ – a point corresponding to the ship's deadweight on the middle CII reference line. This represents some 30% of the distribution of CIIs of ships’ attained operational CII for that ship type in the year 2019. Ships must attain an annual CII rating of ‘C’ or better (i.e. ‘B’ or ‘A’) each year.

If a ship is rated ‘D’ for three consecutive years or ‘E’ for just one year, a set of corrective action plans must be devised to enable the ship to achieve at least a ‘C’ rating for the subsequent calendar year. The plan should describe any additional measures to be taken, the timeline for implementation and the expected impact on the ship's CII rating. Someone from the company should be designated responsibility for monitoring and reviewing the effectiveness of the corrective actions throughout the process. Possible impediments undermining the measures’ effectiveness should be identified alongside possible contingency measures in such an event.

Slow steaming safely

As mentioned above, to meet the EEXI/CII requirements, many existing ships are expected to reduce engine loads as their primary reduction measure due to the fact that little or no modifications would be required to the ship. However, this means that existing ships would have to operate at parameters that may deviate from what they were originally designed for. Most ships are able to adapt operations or equipment settings for slow steaming with few significant problems. Although ships have conducted slow steaming for over a decade with good results, there are some issues that cannot be avoided. Engineers would shoulder this burden and their engine-room workload would increase as they attend to issues such as increased turbocharger fouling and the possibility of soot fires in the exhaust system. An increase in carbon deposits in fuel injectors and piston rings is also to be expected. There have been cases of engine room fires caused by exhaust system fouling, some of which were catastrophic leading to loss of lives, ship and cargo and so there is a need for increased awareness of fire risks associated with soot accumulation when running at low loads.

Of greater concern is whether the crew can easily and safely tap on the full power of their ship's de-rated engine, or for a ship that has an Engine Power Limiter (EPL) or Shaft Power Limiter (SHaPoLi) installed to override them when there is a need to, e.g., navigational situations in rough weather and manoeuvring in difficult conditions. For crews to be familiar with the safety procedures to override the EPL/SHaPoLi systems, engine manufacturers and other experts may need to make relevant information available and provide simple and safe methods to access the required power. This would be another set of risks for the crew to address, plus they must be properly trained and conduct regular drills so they are prepared for such situations. Also, machinery components operating in prolonged low-load or low-speed conditions could be prone to breakdown when the engine or other machinery is suddenly put to higher power modes when the situation calls for it. Certain precautions and routines must be carried out prior to deploying maximum power.

Timeline for implementation

This can be considered an overview of the key, immediate considerations that all ship operators and crew must contend with to prepare for the impending coming into force of the EEXI and CII regulations by 1 January 2023. The SEEMP of ships should be submitted by initial verification to Flags or their Recognised Organisations so that Confirmation of Compliance can be issued to ships by 31 December 2022. Ships will then start collecting and reporting their CII data for 2023, which is the first year of implementation of their SEEMP. The 2023 CII data will have to be submitted from the ship for verification by 31 March 2024. The calculated CII rating of each ship will be verified and issued with a Statement of Compliance. The cycle will repeat for the subsequent year, provided that there is no need for the development of corrective action plans for implementation and verification.

END

12-21 来源:张恩瑜 船舶技术法规研究中心

08-19 来源:连云港海事

04-03 来源: China PSC

04-12 来源:丁一文 邹 婕 世界海运

08-04 来源: 国际海事研究中心

06-18 来源:连云港海事

03-12 来源:信德海事网

01-18 来源:张云嵩、严青 造船技术与海洋平台

03-21 来源:信德海事网

10-16 来源:林新通 世界海运