必须配备破断力230吨的缆绳4根?

要点:本文从SOLAS公约及IMO MSC的两个通函、RIGHTSHIP的图解、MEG4的摘录、DNV和CCS船级社的技术文件,以及实务中,船上在用的缆绳的强度,澳大利亚引水交流时候的内容等,试图给一个问题找到答案。

近日某群有人发了关于船用缆绳配备的通知,内容大概是:某个港口刚召开了安全会议,要求大型木片必须配备破断力230吨的高强度缆绳4根,2024年7月1日起执行,请各船公司认真对待,及时安排,确保船舶在港期间的安全。

群里讨论开了,有人觉得,缆绳断了肯定是强度不够,就该提高强度,对症下药。有的说,明显和IMO的一个修正案冲突,应该是船舶设计最小破断强度SDMBL的100-105%,我知道这事不对劲,但是没敢发话,先找找资料再说。

先是找到了SOLAS公约的II-1/3-8和提到的MSC.1/Circ.1175。而后找到MSC.1/Circ.1619 - Guidelines on the Design of Mooring Arrangements and the Selection of Appropriate Mooring Equipment and Fittings for Safe Mooring 。 提到根据IMO MSC.473(102)决议的对SOLAS II-1/3-8的修正,预计2024.01.01生效the Guidelines on the design of mooring arrangements and the selection of appropriate mooring equipment and fittings for safe mooring., as set out in the annex需要制定缆绳管理计划。

其中明确规定的关键一句是:the Line Design Break Force (LDBF) to be 100% to 105% of the MBLSD; 另外还有定义、目标等几个点,便于理解这句话,单独摘录出来,如下,

2.1 Line Design Break Force (LDBF) means the minimum force that a new, dry, spliced,

mooring line will break at. This is for all synthetic cordage materials.

缆绳设计破断力(LDBF)是进行测试时,一根新的、干燥的、捻接的系泊缆绳的最小破断力

2.9 Ship Design Minimum Breaking Load (MBLSD) means the minimum breaking load of new, dry, mooring lines for which shipboard fittings and supporting hull structures are designed in order to meet mooring restraint requirements.

船舶设计最小破断负荷(MBLSD)是用于设计船舶系泊系统的新的、干燥的系泊缆绳的最小破断负荷,以满足标准环境条件的约束力要求。

3 Goals

The equipment selection and mooring arrangement design safety objectives should be to facilitate safe mooring operations and reduce the risk to shipboard personnel and mooring personnel caused by inappropriate selection and arrangement of equipment and fittings.

5.2.3 The selection of mooring lines should take into account:

.1 the guidance on mooring restraint as per appendix A ofMSC.1/Circ.1175/Rev.1;

2略.……

.3 the compatibility of the MBLSD of mooring lines and the brake capacity of the

mooring winches installed on board;

.4 the Line Design Break Force (LDBF) to be 100% to 105% of the MBLSD;

.5/6/7 略

.8 as far as possible, but at least for lines in the same service (e.g. headlines,

breast lines or springs), mooring lines of the same diameter and type

(i.e. material) should be used.

5.2.4 To avoid overload on mooring winches, fittings and mooring lines, consideration should be given to select mooring winches with brake capacity of less than the ship design

minimum breaking load of the mooring line or with adjustable brake capacity

“缆绳的LDBF 应为船舶设计MBL的100%-105%”这一要求就是缆绳的LDBF要大致等于MBLSD.

另外,MSC.1/Circ.1620也再次提到SDMBL的100%-105%”,如下:

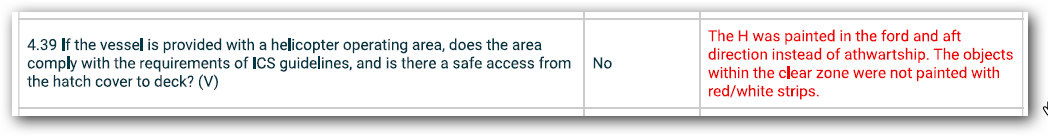

Rightship 这个图,更便于理解这一要求,就是缆绳的LDBF要大致等于MBLSD,但是不能过大,所以也就不会超过系泊附件的SWL(“基于MBLSD的系泊系统附件的相对百分比”),使用时也不会因其强度过大而存在损坏系缆桩或导缆孔的可能,从而保证系泊系统的完整性。

专门提到TAIL是125%,Tail- extension of mooring rope (mainly HSMF), short line with min 11 m length, used for protection of main mooring line, with required strength of 125-130% of SBL。系泊尾索通常由聚酯(PES/PET)、尼龙(PA)或聚酯/聚丙烯 (PES/PET/PP)绳索制成,尾索设计破断力(TDBF)需要高于LDBF,因为在使用中尾索比缆绳的磨损更严重。TDBF应为船舶设计MBL的125%-130%。TDBF是在潮湿的条件下进行测试和确定。

MEG4截图,于雪生船长翻译

DNV关于系、解缆设备要求和CCS技术通告系泊设备检查和维护新通告。也专门提到这个100-105%。

再看某8万吨船上的缆绳,设计破断力650KN,上述通知230吨的缆绳就是大约2300kN,已经远远超出前文提到的文件要求。现在很多船已经执行的MOORING SAFETY MANAGEMENT PLAN也是根据这些材料综合而来。 即便船上采购了此缆绳,各方检查也都会是缺陷。

如果选用的缆绳的设计破断力超过规定的限制,即船舶设计缆绳最小破断力的 100%至 105%,则需要评估系泊设备和附件及其船体支撑结构的参数设置和载荷限制,存在一定的风险性。

实际上,船舶靠泊澳大利亚港口,引水上船后和船长交流信息,专门会问到船舶缆桩的强度,有的船为了省事,直接打印塑封起来,和引水卡一起递给引水。

针对文章开头的问题,理解港口对船舶安全的慎重考虑和对船方的提示, 但是,结合上述文件和实操经验,建议综合考虑再做规定。

实际上,通俗理解,船上缆绳的配备,和船舶设计最小破断负荷(MBLSD)、船上的缆桩、缆车等负荷基本一致,就像上文RIGHTSHIP的文件配图,清晰明了。5万吨的船不能配备18万吨船的缆绳。

再一个,即便缆绳强度大了,还有个rendering point test俗称的打滑试验,刹车就到60%的MBL,缆绳超过这个劲应该秃噜出去的,why?

When moored, winch brakes and lines are expected to keep the vessel safely alongside. When environmental parameters change due to factors such as wind, current, swell, passing vessel surge, excessive list and trim, the winch brakes should be set as the weakest point of the mooring system. Rather than parting mooring lines or damaging mooring winch structures and fittings, the winch brakes should render so that the vessel can be brought back alongside safely. Conversely the vessel should not move away from the berth due to the effect of external forces less than the EN parameters. Regular winch brake render testing and calibration should significantly contribute to safe mooring

本文仅仅是一家之言,匆忙写出,理解不到位的地方,敬请指正。

孙士森 ONBOARD

第14个海员日前夕

于非洲最南端以南 航行中