According to the Global Offshore Wind Report 2022 published by the Global Wind Energy Council (GWEC) on June 29, a total capacity of 21.1GW was connected to the grid in 2021, a new industry record and three times more than in 2020. This brought the cumulative global offshore capacity to 56GW by year's end, equivalent to 7per cent of the total installed wind capacity. “We would like to support this development and highlight it at WindEnergy Hamburg. We are expecting more than 1,350 exhibitors from around the world. 45per cent of them will showcase products or services that are relevant to offshore wind farms. The spectrum comprises the entire value chain, from project planning and financing to production, equipment transport and installation using specialised ships, through to grid connection, operation and maintenance of offshore wind farms,” says Andreas Arnheim, WindEnergy Hamburg Project Director.

GWEC Market Intelligence expects over 315GW of new offshore capacity to be added by 2031. The cumulative global will then be 370GW. 29per cent of the new volume is expected to be operational by 2026. As for floating project development activities, the GWEC report now believes an installed capacity of 18.9GW will likely be operating by 2030, with 11GW in European waters, 5.5GW in Asia and the remainder in North America.

However, GWEC's 10-year overall forecast might well need revising upward significantly in the near future after Russia's invasion of Ukraine has kickstarted comprehensive energy system reform packages in Europe and beyond. The EU plans to achieve full independence from Russian oil and gas imports, with a major part of the resulting energy gap to be filled by accelerating the build-up of new offshore wind capacity. Wind would then generate a much higher portion of clean electricity, which would be partially fed into the grid and partially used to produce hydrogen via Power-to-X. In an additional process, green hydrogen could then be converted to e-ammonia and e-methanol as ship fuels.

Tackling these challenges quickly and decisively requires governments and the industry to make a massive effort. Doing so will open up many opportunities for a wide variety of exhibitors to showcase suitable products and services in the years to come.

Wind turbines are the core segment of the wind energy market. A number of leading suppliers will be present at WindEnergy Hamburg 2022. They will showcase their latest 13-16 MW+ ‘flagships’ and explain to visitors why they prefer medium-speed geared or direct-driven wind turbines, what options for Power-to-X integration are available, what other features and benefits their solutions provide, and what their respective roadmaps look like. This year also marks the planned installation of several 14-16MW prototypes with 236-242-metre rotor diameters.

The German engineering consultancy AEROVIDE has developed 27 full turbine designs since 1983, including the pioneering 5MW Multibrid® design of the 1990's. The exhibitor currently participates in four international 10MW turbine development projects: two medium-speed geared and two direct-drive wind turbines.

The well-established wind turbine gearbox suppliers ZF Wind Power and Flender (Winergy) are shifting focus, expanding their roles to include (co-)development and manufacture of semi- and fully-integrated geared powertrains. The use of journal bearings in gearboxes has now become standard practice, helping to propel gearbox torque densities to over 200Nm/kg.

Fraunhofer IWES will commission its new test bench this summer which can accommodate rotor blade lengths of more than 120m. Vestas is the first customer to take advantage of Fraunhofer's new facility, testing a 115.5-metre blade to be fitted on the V236-15.0MW.

The current blade length record is roughly 118m for Ming Yang's MySE16-242; meanwhile well-informed sources suggest that 17-18MW wind turbines with 270m+ rotors are on the horizon.

Jack-up vessels for 20MW+ wind turbines with e-fuel-ready engines

Anticipating these developments, leading international offshore installation contractors are ordering new installation vessels for next-generation 20MW+ turbines. These ships will be fitted with powerful cranes to handle the resulting foundation, nacelle and rotor sizes. For example, in late 2021 the Dutch offshore contractor Van Oord, an offshore wind market leader, ordered a new jack-up vessel capable of installing turbines of up to 20MW.

As a novelty, the engines of this vessel will be able to run on e-methanol and operate with a very small CO2 footprint, according to Van Oord. The vessel is expected to enter the market in 2024. Van Oord also offers soil preparation, cable laying, scour-protection and other offshore services by deploying its own fleet of dedicated vessels and equipment, and develops monopile and jacket foundations in-house. Furthermore, the Rotterdam-based company participated in the development and demonstration of the world's first submerged slip joint, an innovative method for joining monopile foundation sections without requiring grouting or bolt joints.

“For Van Oord, WindEnergy Hamburg provides an excellent opportunity for meeting industry players from all over the world. The knowledge-sharing and networking opportunities have proven to be highly valuable elements. With North-Western Europe the largest market for offshore wind, Hamburg is for us and our experts a great location for hosting this event”, said Managing Director Arnoud Kuis.

Feeder solution for USA

Belgium's DEME Offshore and Rotterdam-based Barge Master are introducing a high-tech feeder solution for US offshore wind farms. The concept fully complies with the Jones Act, which prohibits the transport of goods and passengers between US ports by foreign companies and ships.

Working closely together, the two exhibitors have developed integrated motion-compensation technology for deployment in a pioneering feeder concept for the Vineyard Wind 1 project – the first commercial-scale US offshore wind farm. This integrated high-tech solution will allow wind turbine components to be transported from US ports to DEME's offshore installation vessels. When a feeder arrives alongside an installation vessel, the Barge Master motion-compensation technology will ensure safe lifting operations, increasing efficiency.

“We are providing the most competitive feeder solution in the market by utilising proven technology. Combining our motion-compensated feeder platforms with existing US maritime equipment turns existing barges into high-tech feeder solutions and keeps the CAPEX and OPEX low when compared to other concepts. We are confident this feeder solution is perfect for the US offshore wind market today as well in future,” said Martijn Koppert, CEO of Barge Master.

He welcomes Hamburg visitors to discuss opportunities for deploying motion compensation technology for floating wind, as well, from the pre-installation phase to O&M activities ‘where no ideal solution has been found yet.’

Floating turbine mooring and monitoring

The Dutch company Vryhof has been supporting floating wind developers since 2009 when it started supplying mooring systems to Statoil's Hywind Demo 2.3MW spar prototype, and to Principle Power's 2MW semi-submersible WindFloat prototype a year later. Vryhof will showcase two main innovations at WindEnergy Hamburg. Both solutions have been demonstrated at Stiesdal Offshore Technologies' industrialised full-scale TetraSpar Demonstrator floater which has been operating off the Norwegian coast since December 2021.

The STEVADJUSTER is an innovative, cost-effective and time-saving solution for chain adjustment, pre-tensioning of moorings, and easy connection or disconnection of anchor lines. DELTRACKER is Vryhofs' proprietary stand-alone software package used to track the lifecycle and usage of mooring equipment on an individual component or line-by-line basis.

Neil Schulz, Business Development Director at Vryhof, said: “The rapid rise of offshore renewables calls for new solutions. Vryhof believes in mass deployment of floating wind and wants to help this industry move forward to a commercial level. We consider WindEnergy Hamburg as one of the key events to share our latest experiences with STEVADJUSTER and DELTRACKER with potential and existing clients.”

Safe people transfer

Providing safe transfer of personnel from crew transfer vessels to turbines is essential, with hardware offers ranging from Ampelmann’s motion-compensated walking bridges to transfer-basket solutions. The Danish supplier of davit cranes Seasight Davits will present its innovative ‘Spider’ system in Hamburg. This is an upgrade for their davit cranes mounted at many offshore turbine platforms, combined with a transfer basket enabling the use of the same crane for transferring both personnel and cargo. A remote-control feature allows the crane operator to activate the crane from the ship while approaching the turbine foundation.

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

WOODSIDE AND CHINA RESOURCES AGREE LONG-TERM LNG SU

WOODSIDE AND CHINA RESOURCES AGREE LONG-TERM LNG SU  Shanghai Yangshan Port Bunkered Two LNG Powered Con

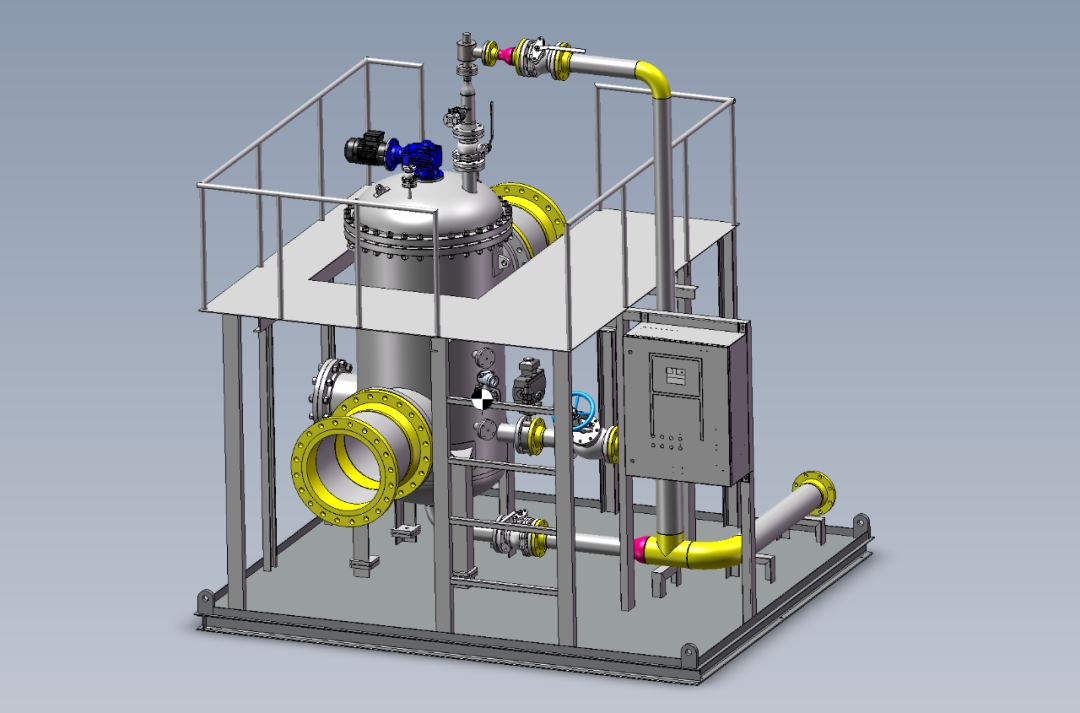

Shanghai Yangshan Port Bunkered Two LNG Powered Con  Headway successfully delivers filtration skid solut

Headway successfully delivers filtration skid solut  Celebrating the Launch of “Green Energy Pearl” –

Celebrating the Launch of “Green Energy Pearl” –  PIL and SSES complete the inaugural LNG bunkering o

PIL and SSES complete the inaugural LNG bunkering o  BW LNG secures e-procurement deal with Procureship

BW LNG secures e-procurement deal with Procureship