Alfa Laval has signed its first contract for the ammonia fuel supply system, FCM Ammonia, reinforcing its position as a frontrunner in developing solutions for decarbonizing the maritime industry. The FCM Ammonia will be installed onboard seven LPG/ammonia carriers for Tianjin Southwest Maritime.

Ammonia-powered shipping becoming a reality

As a front-runner in enabling the use of ammonia, Alfa Laval has achieved a significant milestone by securing the contract for the ammonia fuel supply system, highlighting its technological readiness to handle ammonia as fuel. The FCM Ammonia will be installed on a CSSC Huangpu Wenchong shipyard in China for ship owner Tianjin Southwest Maritime (TSM). The installation will commence with three 25,000 cubic metre vessels, followed by four 41,000 cubic metre vessels.

"Through research, product development, and strategic partnerships, we are building the solutions needed for a safe and efficient transition to low-carbon alternative fuels," says Peter Sahlen, Head of Marine Separation, Fuel Supply System & Heat Transfer, Alfa Laval. “Our deep experience with fuels like methanol and LPG has given us a head start with ammonia, and this first contract validates our commitment to driving decarbonization in shipping with reliable and innovative solutions.”

Collaborative development drives innovation

The FCM Ammonia contract follows extensive testing and development conducted in close collaboration with Swiss engine designer WinGD. In December 2024, comprehensive testing of the full fuel supply system, fuel valve train, and vent treatment system commenced at WinGD’s Engine & Research Innovation Center (ERIC) in Winterthur, Switzerland. These tests, utilizing test benches delivered by Alfa Laval Monza, will first validate key components for the vent treatment system, also called the ammonia release mitigation system, and then secure control logic and performance at varying engine loads.

"Collaborating with trusted partners such as Alfa Laval has been instrumental in bringing these new clean-fuel technologies to market, making ammonia-powered shipping a reality. This partnership, along with our joint R&D efforts, underscores our shared commitment to the clean energy transition to enable a sustainable future for shipping,” says Sebastian Hensel, Vice President, Research & Development, WinGD.

The research and development project with WinGD for testing FCM Ammonia has laid a strong foundation for its commercial adoption. This is further evidenced by K Shipbuilding receiving Approval in Principle (AIP) from ABS in December 2024 for the design of an ammonia dual-fuel MR1 tanker. The project, a collaboration between South Korea’s shipbuilder K Shipbuilding (KSB), Alfa Laval, WinGD, and the classification society American Bureau of Shipping (ABS), saw Alfa Laval contribute to the design of the entire fuel system, including the ammonia fuel supply system, fuel valves train, and vent treatment system, with Alfa Laval also adding an Aalborg ammonia dual-fuel boiler system to the project scope. This achievement marks the first instance of a combined vent treatment system incorporating both a water absorber and burning.

The success of the rigorous testing project is generating trust across the industry, and the recognition from class societies further confirms that ammonia can be a safe and viable marine fuel when backed by expert collaboration and robust system design.

The first FCM Ammonia unit for TSM is scheduled for delivery at the end of 2025. The contract with TSM, a current customer for FCM LPG, Alfa Laval fuel supply system for LPG, further underscores Alfa Laval’s key role in providing comprehensive fuel solutions to meet the evolving needs of the maritime industry.

source: Alfa Laval

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Sea-Cargo and Norsepower continue their collaborati

Sea-Cargo and Norsepower continue their collaborati  Alfa Laval expands its portfolio with ultrasonic an

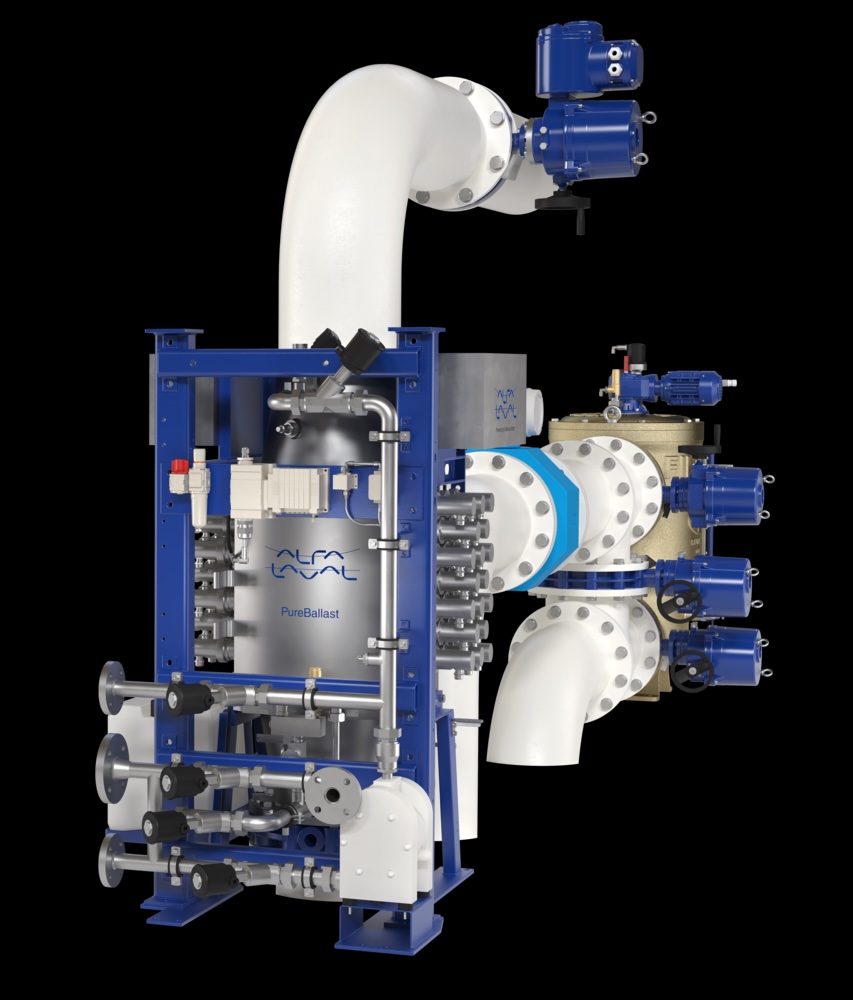

Alfa Laval expands its portfolio with ultrasonic an  Alfa Laval PureBallast 3 Ultra secures orders from

Alfa Laval PureBallast 3 Ultra secures orders from  RobotPlusPlus Wows Maritime Professionals with Carg

RobotPlusPlus Wows Maritime Professionals with Carg  Alfa Laval secures first contract for ammonia fuel

Alfa Laval secures first contract for ammonia fuel  GNV Tests RINA’s Machine Learning and Predictive

GNV Tests RINA’s Machine Learning and Predictive