Latest BERG Propulsion project to upgrade the fuel economy and emissions performance of a German-flagged shortsea container ship on charter to CMA CGM exceeds expectations when it comes to the efficiency of older ships.

A 2007-built containership has been redelivered as one of the most efficient vessels of its type, according to its owner, following a DNV-approved retrofit and upgrade project requested by charterer CMA CGM.

The leading shipping and logistics group asked German owner Reederei Rambow to undertake a comprehensive package of efficiency optimization measures onboard the 868TEU capacity Henneke Rambow to match current and anticipated fuel efficiency and emissions performance requirements.

The joint project saw CMA CGM and Reederei Rambow work with BERG Propulsion to realise a series of efficiency gains, after BERG undertook a holistic review and data-based analysis of the ship’s propulsion system, including its existing propeller. The assignment is the latest in a series of BERG retrofit projects which help older ships enhance their efficiency and respond to expectations on carbon intensity.

“The Henneke Rambow project is an effective example of collaboration between owners, charterers and systems integrators, working together to optimize ship performance,” commented Mathieu Gubert, VP Chartering CMA CGM.

According to David Sakandelidze, Account Manager, Energy & Efficiency, BERG Propulsion: “As well as ensuring that the ship maintained its competitiveness, efficiency and sustainability for the years to come, the brief was to achieve performance gains without altering the vessel's existing operational profile.”

With Henneke Rambow consistently operating below the service speed envisaged at the time of its delivery, BERG’s systematic review focused on optimizing the propulsion solution for fuel economy.

The project saw new BERG propeller blades installed that are hydrodynamically optimized for its full operational profile. The owner’s retrofit project also included optimization of the ship’s bulbous bow for a revised operational matrix.

Surgical interventions

However, where systems were concerned, BERG’s chosen approach focused on maintaining as much of the original equipment as possible, making what Sakandelidze described as "surgical interventions” to optimize performance for lower speed.

Key upgrades included the installation of a Net Frequency Stabilizer as part of ship's power management system to improve power system efficiency without compromising functionality or the ship’s existing safety measures. This allows the shaft generator to operate at variable speeds while still providing a stable frequency and voltage to the main switchboard in order to ensure efficiency without compromising operational versatility.

Sven Rambow, Rambow Bereederungs GmbH & Co. KG, said: “Following this upgrade, Henneke Rambow is demonstrating a remarkable performance improvement which ensures that this vessel will be one of the most efficient of this type for the decade ahead.”

Sakandelidze described the retrofitted BERG MPC800 propulsion control system as the “brains” behind integrating the new features, in a solution which also features the company’s Dynamic Drive technology. The MPC800 system controls shaft line propellers, thrusters and associated systems in all types of vessels: integrated with the vessel’s four-stroke engine, the solution enables optimal propeller operations at all shaft speeds. Dynamic Drive enables setting upper limits for vessel speed or fuel consumption by optimizing propeller pitch and rpm. If fuel is the priority, the algorithm selects the rpm/pitch to optimize engine performance.

With the International Maritime Organization’s Carbon Intensity Index increasingly factoring in vessel performance considerations for owners and charterers Sakandelidze emphasizes that integrating these performance upgrades required almost no modifications to the existing electrical equipment onboard.

Planning for the future

“A challenging path from the engineering and planning perspective can lead to solutions and implementation that keeps things simple and retains as much original equipment as possible,” Sakandelidze told BTJ. “It’s an approach that pays off on many levels.”

“The vital role smaller container ships play in global logistics can sometimes be overlooked, but in this case the enhanced performance is extraordinary, with our data indicating that the overall post-project efficiency gains are substantial,” said Magnus Thoren, Account Manager, Energy & Efficiency, BERG Propulsion. “By taking care of the total propulsion solution, Berg has worked as the service and technology partner with CMA CGM as charterer and Rambow as a well-known owner so that a valuable asset remains highly competitive.”

BERG has undertaken a series of retrofits focusing to optimize older ships to ensure that they remain competitive in the era of carbon intensity monitoring and emissions trading.

Earlier this year, specialized ship manager Chemfleet confirmed that the IMO II tanker YM Miranda had achieved around 10% in fuel savings after replacing the ship’s existing control system with BERG’s MPC800 technology. Chemfleet has decided to upgrade three additional 6,970 dwt sisterships with Berg MPC800M control system onboard, in a solution that will also integrate Berg’s Dynamic Drive Software.

Other recent examples where BERG’s Dynamic Drive technology has been specified include the Shipsveerf Ferus Smit B.V project to build 10 newbuildings Swedish owner Erik Thun. Here, the integrated drive solution has been selected on the basis of its ability to help save 10% of fuel, rising to 20% in some operational conditions, across four 5,100 dwt ’Troll-Max’ dry cargo vessels and six 7,999 dwt coastal ‘Eco Tankers’.

In a recent retrofit where BERG’s MPC800 control was already onboard, Oslo-based Bulkship Management worked with the supplied on straightforward ‘EPL for EEXI’ power limitation solution across 10 ships trading in US Gulf and Caribbean waters. EPL’s limiting effect on the ship’s BERG MPP950 CPP brought DNV acceptance of the system’s performance as an effective EPL solution. Bulkship has now confirmed orders to install across nine more ships.

“While there is no one-size-fits-all solution, BERG is helping ship owners by assessing potential efficiency improvement options during this transitional period in ship decarbonization,” said Martin Linder, Sales Manager, Energy & Efficiency, BERG Propulsion. “We are working closely with ship owners to deliver on with their energy efficiency needs, whether they are working through the EEXI and CII transition, focusing on fuel efficiency or leading the way on decarbonization.”

source: Berg Propulsion

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Sea-Cargo and Norsepower continue their collaborati

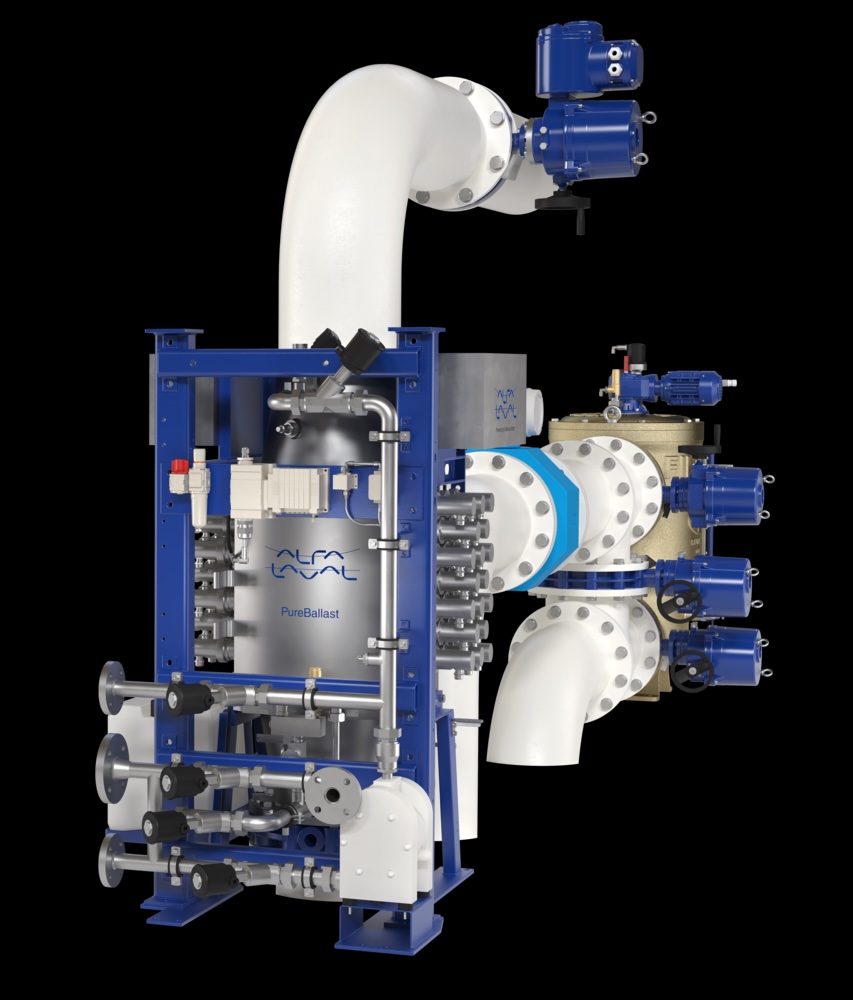

Sea-Cargo and Norsepower continue their collaborati  Alfa Laval expands its portfolio with ultrasonic an

Alfa Laval expands its portfolio with ultrasonic an  Alfa Laval PureBallast 3 Ultra secures orders from

Alfa Laval PureBallast 3 Ultra secures orders from  RobotPlusPlus Wows Maritime Professionals with Carg

RobotPlusPlus Wows Maritime Professionals with Carg  Alfa Laval secures first contract for ammonia fuel

Alfa Laval secures first contract for ammonia fuel  GNV Tests RINA’s Machine Learning and Predictive

GNV Tests RINA’s Machine Learning and Predictive