With around 60 exhaust gas scrubber references, naval architecture and marine engineering firm Foreship suggests that better than expected return on investments from open loop systems will translate into further orders once coronavirus-related uncertainties pass.

Foreship's scrubber selection recommendations to ensure ship emissions meet IMO 2020 0.1% fuel sulphur content equivalence are fully independent and based on cost, complexity and operating profile. With services ranging from feasibility studies to concept design, basic design, detail design and supplier evaluation, Foreship has extensive experience of open loop, closed loop and hybrid systems, a variety of class rules and yard installations in Europe, North America and Asia.

Olli Somerkallio, Chief Operating Officer, Foreship, says that the majority of the hybrid systems the company has worked on have been destined for cruise ships or ROPAX vessels, where vessels spend more time operating coastally and in-port. However, lower cost open loop scrubbers have represented a larger part of the company's workload, with owners switching to lower sulphur fuels where port restrictions on washwater demand it.

“It's understandable that some local authorities take a negative view on acidity in washwater and the presence of heavy metals, no matter how low the concentrations, especially where water exchange rates are not high,” he says. “Hybrid scrubbers that switch to closed loop operations in port certainly provide one option but the other remains to install an open loop system and manage a switchover to low sulphur fuels in port.”

Somerkallio says that the combination of Covid-19 and cut-throat oil pricing has eaten into the differential between high sulphur and low sulphur content fuel oils, leading demand for scrubbers to stall. The circumstances also had consequences for future scrubber technology demand.

The cruise ships needing hybrid scrubber systems to accommodate closed loop operations in waters identified as especially sensitive had already been equipped, while Covid-19 ad driven some older vessels that might have been hybrid candidates to scrap.

The total cost of open loop scrubbers including equipment and installation is significantly lower than is the case for hybrid systems, and owners that have committed to this technology are reporting returns on investments far more rapid than anticipated, Somerkallio reports. “When oil prices recover, we expect this type of scrubber to attract significant new investment,” he says.

“For cargo ship owners, the fact that the closed loop needs alkali in significant volumes will always make it an expensive option. Although lower fuel cost in port can shift the economics in favour of the hybrid option for some ships, for cargo ships the cost of the closed loop operation kills the economics of the scrubber.”

Somerkallio acknowledges that criticisms are levelled at open loop scrubbers based on sulphurous washwater but emphasises that only specific ports and coastal waters block their use. While the efficiency indexes driving IMO regulations favour LNG over HFO, December's Marine Environment Protection Committee nonetheless pointedly replaced the phrase 'liquid effluents' with 'discharge water' in its latest scrubber guidelines evaluation.

Somerkallio adds that new research from Tampere University, the Finnish Meteorological Institute and the VTT Technical Research Centre show that using exhaust gas cleaning systems in combination with HFO result in lower particulate emissions than marine gas oil.

“Whatever the critics might say, if there was an outright ban on the open loop, I believe there would only be a very small number of scrubber installations altogether each year. I don’t believe that would be an environmentally desirable outcome.”

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Sea-Cargo and Norsepower continue their collaborati

Sea-Cargo and Norsepower continue their collaborati  Alfa Laval expands its portfolio with ultrasonic an

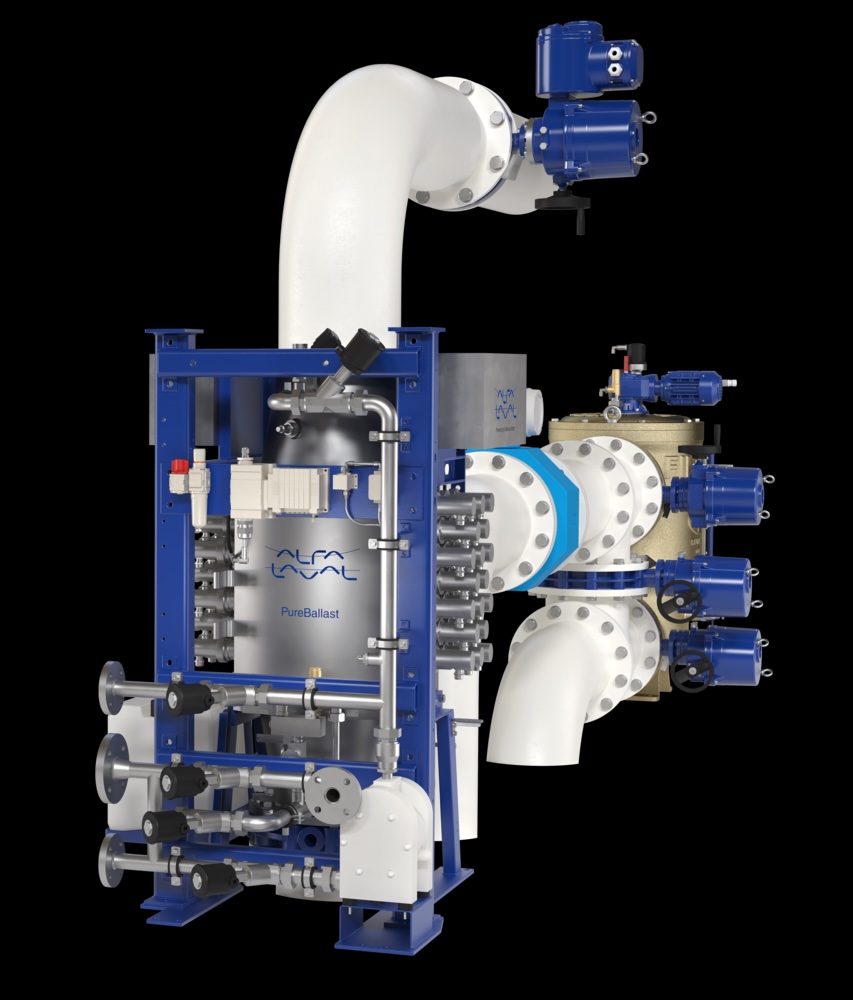

Alfa Laval expands its portfolio with ultrasonic an  Alfa Laval PureBallast 3 Ultra secures orders from

Alfa Laval PureBallast 3 Ultra secures orders from  RobotPlusPlus Wows Maritime Professionals with Carg

RobotPlusPlus Wows Maritime Professionals with Carg  Alfa Laval secures first contract for ammonia fuel

Alfa Laval secures first contract for ammonia fuel  GNV Tests RINA’s Machine Learning and Predictive

GNV Tests RINA’s Machine Learning and Predictive