螺旋桨不能达到完全浸没的风险和建议

作者 于学雷 赵立帅

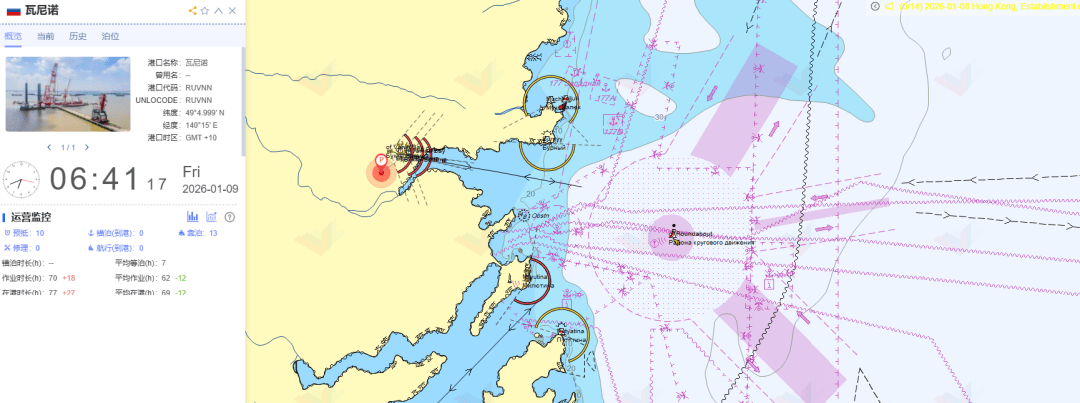

船舶在空载状态下,进出船坞,少量装货或者在有最大吃水限制的区域航行时可能会出现螺旋桨不能完全浸没的情况

船舶在螺旋桨浸没不能达到100%时运行,将导致船舶性能损失、主机超速和应力或者损坏船舶的机械设备

艉轴管和轴系的基本设计考虑的是螺旋桨完全浸没。当螺旋桨桨叶尖端有点接近水面时,设计裕量会引起小量的轻微偏心螺旋桨载荷

If propeller is not completely immersed, it will result in:

如果螺旋桨没有完全浸入水中,将导致:

excessive eccentric thrust 偏心推力过大

increased downward bending moment at the aft end of propeller shaft, leading to higher edge loading of stern tube bearing.

螺旋桨轴尾端向下弯矩增大,导致艉轴轴承边缘负荷增大。

breakage of oil film and ineffective hydrodynamic lubrication in the aft stern tube bearing.

艉轴管轴承润滑油膜破裂,流体动力润滑失效

increased shaft system vibrations增加轴系统振动

increased cavitation of propeller螺旋桨气蚀增强

When propeller and shaft lines are operated outside the design criteria there is a risk of:

当螺旋桨和艉轴在设计标准之外运行时,存在以下风险:

Stern tube seal leakage 。尾轴轴封泄漏(向外漏油或者向内漏水)

Increased wear of stern tube bearing 艉轴管轴承磨损加剧

Fatigue failure and subsequent damage of stern tube bearings.

艉轴管轴承疲劳破坏和随后造成的损坏。

Wear and damage to shaft line bearings.艉轴轴承的磨损和损坏

Cavitation and wear of propeller。螺旋桨桨叶气蚀和磨损

When the shaft comes into direct physical contact with the material of the bearing, the temperature of the bearing will rise, and in most situations, this will happen at an exponential pace.当轴与轴承直接接触时,轴承的温度将上升,在大多数情况下,这将以指数速度发生。

Bearing damage was seen even with a slower rate of temperature rise when it occurred in a singular instance that involved lengthy operation beyond the alert limit, which is generally set at 65 degrees Celsius. The damages that were documented led to repairs that were both expensive and time-consuming.轴承损坏即使在温度上升速度较慢的情况下也会发生,如果它发生在一个涉及长时间超过警戒极限(通常设定为65摄氏度)的情况下。记录在案的损坏导致了既昂贵又耗时的修复。

Failure of the bearings can increase the chance of the main propulsion function capacity being lost entirely or significantly reduced, and in rare instances, it can be harmful to the propeller shaft if steel-to-steel contact occurs.轴承的故障可能会增加主推进功能能力完全丧失或能效显著降低,在极少数情况下,如果钢对钢发生接触,可能会对传动轴有害

If long-term operation with incomplete propeller immersion does not result in an immediate failure, the risk of fatigue-related bearing failures arising out of excessive cyclic loading and associated shear forces on the bearing will co-exist. These failures are caused by excessive cyclic loading and associated shear forces on the bearing.

如果在螺旋桨浸没不完全的情况下长期运行不会导致立即失效,则由于过度循环加载而引起的疲劳相关轴承失效的风险以及轴承上的相关剪切力将同时存在。这些故障是由过多的循环载荷和轴承上的相关剪切力引起的。

Under normal circumstances to avoid the above-mentioned issues, the minimum draft aft must be:

在通常情况下,为避免上述问题,最低起吃水必须为:

Draft required for min. 100% propeller immersion (as per Trim & Stability book) + 0.6 meters.至少100%螺旋桨浸泡所需的吃水(根据配平和稳定性手册)+0.6米

During navigation in stormy conditions, a ship can think about postponing or eliminating trim optimization altogether, bringing the ship to an even keel instead, or adjusting the trim by the stern as necessary depending on the severity of the weather.

If the propulsion shaft system is experiencing an abnormally high amount of vibration, you may want to consider increasing the aft draft in order to reduce the level of vibration.

在风暴条件下航行时,船舶可以考虑完全忽略纵倾,而是将船舶调整到平吃水,或根据天气的恶劣程度调整为尾倾。如果推进轴系统出现异常高的振动,你可能需要考虑增加船尾吃水,以降低振动水平。

When the propeller is only partially submerged during operation, this can result in an excessively eccentric force on the propeller and, therefore, a downward bending moment on the shaft. Because of this, there is a possibility that the aft bearing will experience increased localized loads (edge loading), as well as surface pressure, as a consequence of the increased relative slope and lower bearing contact area.

当螺旋桨在运行过程中仅部分被淹没时,这可能会导致螺旋桨上的过度偏心力,因此,轴上的向下弯曲力矩。因此,由于增加的相对斜度和较低的轴承接触面积,存在后轴承将经受增加的局部载荷(边缘载荷)以及表面压力的可能性,这是增加的相对斜率和较低的轴承接触面积的结果。

Because the design criteria do not account for localized bearing stresses operating on a reduced contact area, this can result in the complete or partial loss of an effective hydrodynamic oil layer with a minimal thickness.

由于设计标准没有考虑在减小的接触面积上工作的局部轴承应力,这可能导致最小厚度的有效流体动力油层的完全或部分损失

As a result, there is a possibility that the bearings will be damaged in the future as a consequence of the incomplete propeller immersion when unusual operating conditions are present.

The degree of lack of propeller immersion, revolutions per minute (RPM), and power all have a role in the generation of the additional bending moment.

因此,非常规操作时,由于螺旋桨的不完全浸没,轴承将来可能会损坏。螺旋桨浸没的程度、每分钟转数(RPM)和功率都会增加弯矩影响力

To provide further clarification on this topic, the bending moment is related to the thrust force, which in turn is proportional to the square of the RPM. Because of this, increasing the RPM in a circumstance where the propeller is partially submerged adds an exponentially greater degree of risk.为了进一步说明这个问题,弯矩与推力有关,推力与每分钟转速的平方成正比。因此,在螺旋桨部分没入水中的情况下,增加转速会增加风险指数

In exceptional cases it may not be possible to achieve 100% propeller immersion + 0.6m, for example:在特殊情况下,可能无法实现100%螺旋桨浸入+0.6m,例如:

Vessel going in/out of dry-dock 进出船坞

Phasing in/out of a certain trade

Low cargo load 少量装货

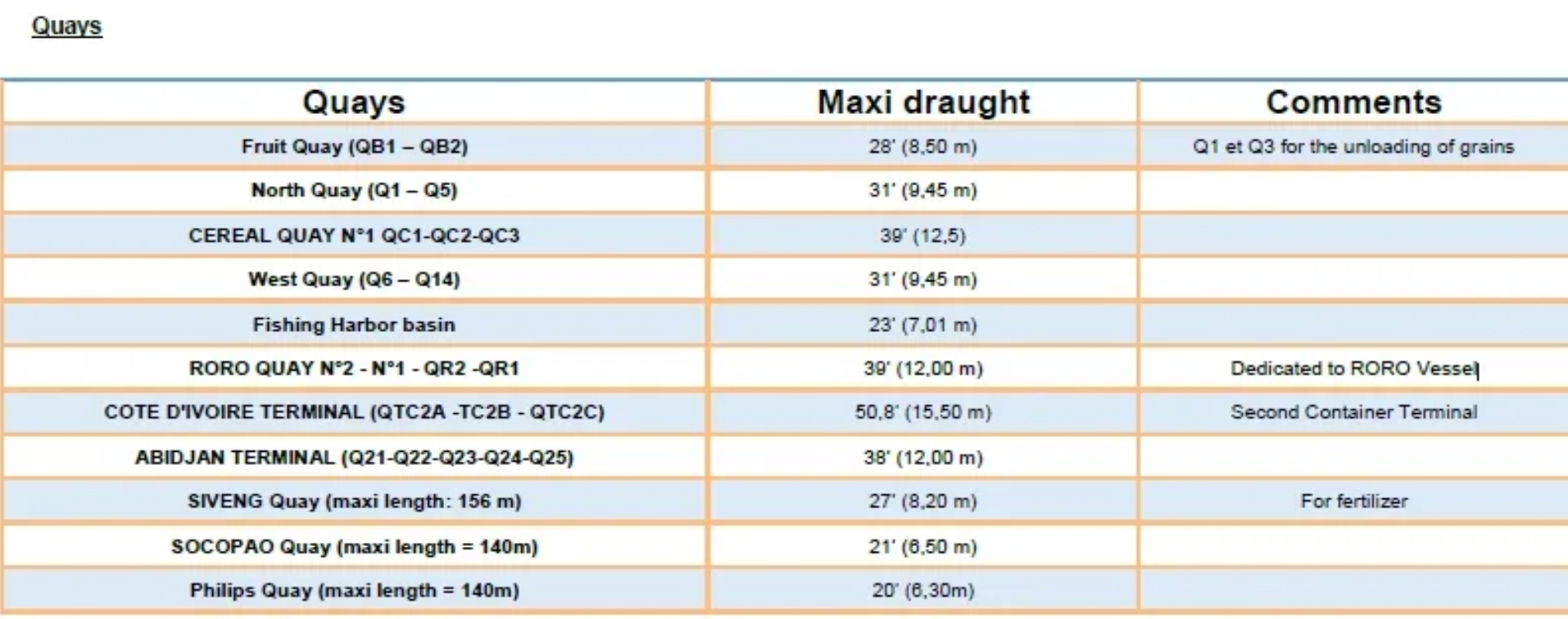

Vessel trading in areas with limiting factor e.g. minimum water depth and/or port restrictions on maximum vessel draft.船舶在有限制因素的区域航行,例如最小水深和/或最大吃水的港口限制

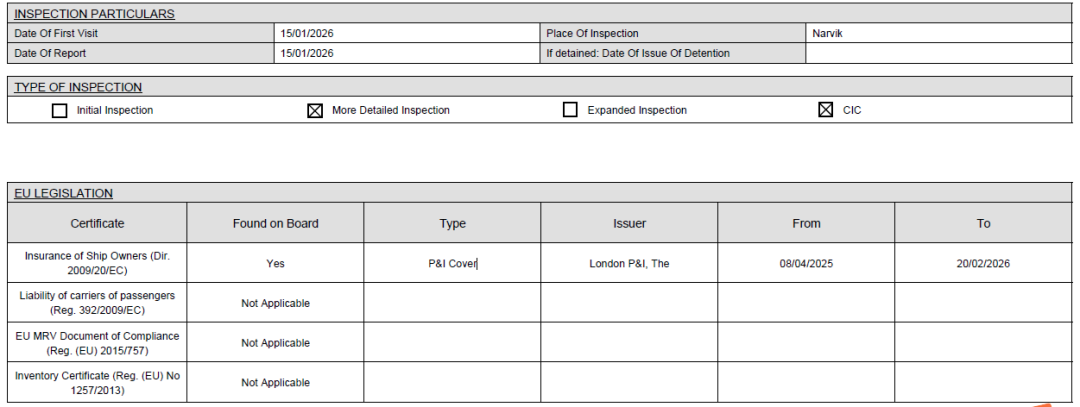

In such cases vessel superintendent is to be informed to ensure that appropriate measures are planned, and following risk mitigation measures are put in place:。在这种情况下,应通知船舶主管,以确保计划采取适当的措施,并落实以下风险缓解措施:

All options to increase propeller immersion to greater than or min. 100% must be considered, and cargo planner may be contacted if any concerns with ballast intake and/or stress & stability limits.

通过任何可行的方法增加螺旋桨浸末大于100%,压载和装卸货计划必须符合应力和剪力的要求

At propeller immersions between 87% to 100%, the maximum load on main engine should not exceed ME power corresponding to “Half Ahead”.

当螺旋桨浸没在87%至100%之间时,车钟不要超过Half ahead

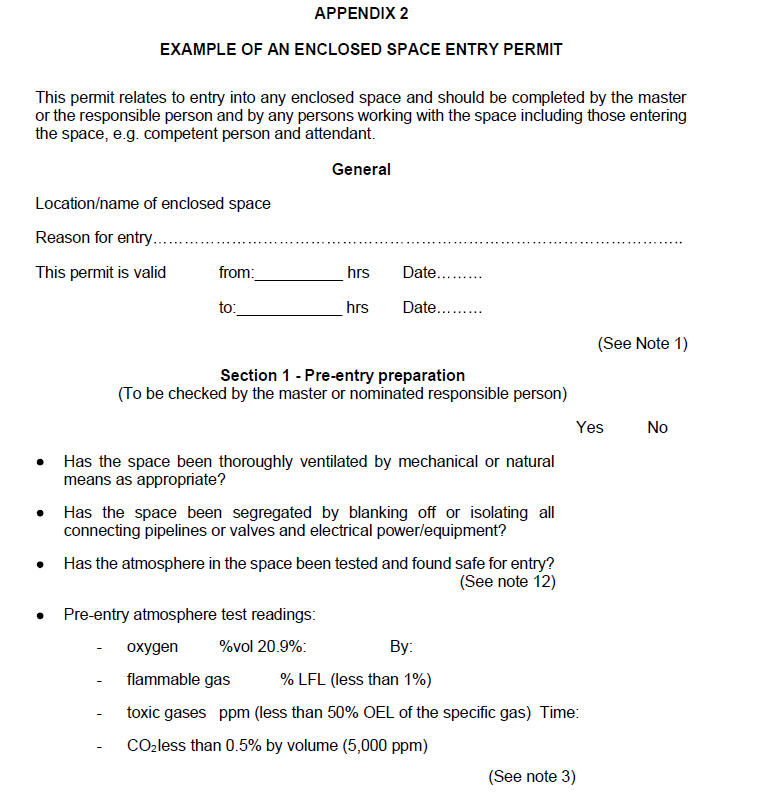

It must be ensured that all stern tube and intermediate bearing temperature alarms are checked, and slow down functions (Manual or Automatic) are tested.

必须确保所有艉轴管和中间轴承温度报警器都检查过,减速功能(手动或自动)都测试过。

Vessels equipped with ‘Manual Slow Down’ require immediate attention during a high temperature alarm..

装有“手动减速”装置的船舶在高温报警时需要立即注意。

In general, temperature alarms for stern tube bearings are recommended to be set at:

High Alarm setting 62 ºC

High High Alarm and Slow Down 65 ºC

Other settings may have been applied originally and should only be changed in agreement with the superintendent.

。

一般情况下,艉轴管轴承的温度报警器建议设置在:

高报警设置62°C

65°C高报警和减速

其他设置必须经过机务同意

On some vessels additional alarms and checks are available to ensure stern tube safety and proper functioning.在某些船舶上,附加的警报和检查可用于确保尾管的安全和正常运行

Temperature rises max. 5 ºC/min (Slow Down)温度上升最大。5摄氏度/分钟(减速)

ΔT Max differential temp. between SW and S/T temp. (Slow Down)最大温差。(减速)

Increased monitoring of stern tube bearing temperatures, stern tube seal drains and LO water content during the entire low draft operation.在整个低吃水操作期间,加强对艉轴管轴承温度、艉轴轴封排水和LO水含量的监测。

Vessel crew must ensure efficient stern tube cooling by always keeping the cooling water tank around the stern tube filled with fresh water.

船员必须确保有效的艉轴管冷却,使艉轴管周围的冷却水箱始终充满淡水。

As mentioned above LO water content should be checked regularly due the entire low draft operation, as in case of stern tubes with white metal bearings, water in the lubricating oil can cause severe damage with considerable repair expense and time loss. On the other hand, Wartsila Railko stern tube bearings can work with a limited amount of sea water in the lubrication oil without damage to the bearings.

如上所述,由于整个低吃水运行,应定期检查LO含水量,对于带白色金属轴承的艉轴管,润滑油中的水可能会导致严重损坏,造成相当大的修理费用和时间损失。另一方面,瓦锡兰Railko艉管轴承可以与润滑油中的海水数量有限,而不会损坏轴承。

In case that high temperatures occur in the stern tube bearing:

在艉轴管轴承出现高温时:

Reduce shaft revolutions immediately to Dead Slow. In case protection system is only set up to give an alarm or manual Slow Down, it is of high importance that duty officer immediately reduce rpm on the ME telegraph.立即将轴转速降低到“DEAD SLOW”如果保护系统仅用于发出警报或手动减速,值班驾驶员应立即降速,这一点非常重要。

Keep rudder position at mid-ship position as far as possible.

保持正舵

Monitor stern tube bearing temperatures rise, if temperature is stabilizing keep RPM and monitor that temperature is gradually going down.

监视艉轴管轴承温度上升,如果温度稳定保持转速,并监视温度是否逐渐下降。

In case temperature is continuously decreasing, continue with Dead Slow RPM until temperature is stabilized below sea water temperature + 30 ºC;

在温度持续下降的情况下,继续保持DEAD SLOW,直到温度稳定在海水温度+30°C以下;

At above stages never stop the Main Engine, as this could result in the tail shaft being bent due to spot heating of the propeller shaft.

在以上情况下,切勿停止主机,因为这可能导致尾轴因传动轴的局部发热而弯曲。

If stern tube temperature does not decrease or rises above 85°C with above procedures, then:如果按照上述程序,艉管温度没有降低或升高到85°C以上,

则:

Stop the Main Engine;停车

Engage the turning gear immediately and start turning of shaft to avoid spot heating of the propeller shaft;立即启动盘车装置,开始盘车轴,避免传动轴局部发热

Monitor cooling down of stern Tube;监控艉管冷却;

Turning gear must not be stopped during this process.在此过程中,盘车装置不能停止

Obviously, vessel must liaise with the technical manager and superintendent to coordinate on further actions in case of reduction in shaft revolutions due to abnormal conditions in the stern tube system and above checks are to be initiated subject to safe navigational conditions.

显然,船舶必须与技术部门和机务经理联系,以协调因艉轴管系统异常导致轴转数减少的进一步行动,并在安全航行条件下启动上述检查。

在工作过程中总结的一些内容,希望能给船员兄弟提供一些便利,如有不当的或者需要改进的地方也希望同行师傅给与指正,众人拾柴火焰高,船员兄弟之间相互帮助,让我们枯燥的生活多点乐趣,让我们繁琐的工作变得相对简单。。。。。。