Deck machinery and systems of ships are continuously subjected to harsh weather and corrosive environment. Machinery such as cargo cranes and associated auxiliaries are important for commercial ship operations, and any problem with them can lead to extended port stay, damage to the property or even loss of life.

The deck crane, a necessary machinery on ship’s deck, does not only belong to navigating officer’s worksheet. The ship’s marine engineer has to ensure that all the hydraulics and electronic components of the crane are working efficiently and in coordination. The maintenance and smooth operation of the ship’s cargo crane require teamwork of seafarers onboard the vessel.

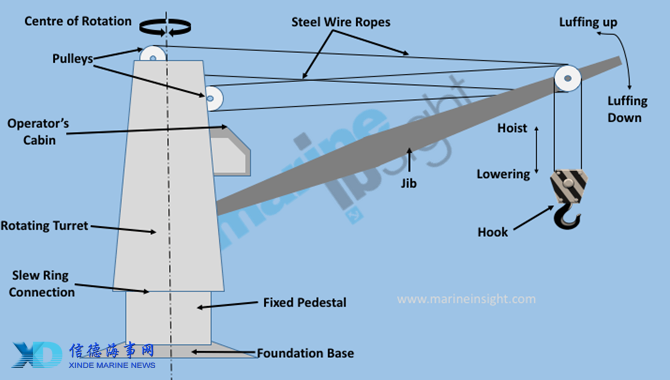

A deck cargo crane mainly comprises of these sections and equipment:

Base Structure of the crane: The base structure of the crane is an extra strengthened structure, on which, the pedestal of the crane is mounted.

Fixed Pedestal: This structure equally distributes the stresses to the base structure and also incorporates the moving turrets via a slew ring connection to enable the rotational movement of the crane

Moving Turret: Moving turret is where the operator’s cabin is situated, and the crane Jib is connected to it. As per the make and design, the turret can move 360 degrees to its centre of rotation.

Jib Arm: The Jib arm is what carries the load. The arm can be hydraulically moved in four directions- Up, down, back and forward. The moving turret performs the rotational movement of the crane to transfer the load.

Hoist with wire: The hoist is hanged at the end of the Job arm with the use of steel wire ropes, which are connected to the winch drum for lifting or lowering weight for transfer.

Hydraulic and electric equipment: The hydraulics and electrical machinery are an integral part of crane operation. Hydraulic oil pressure results in the movement of jib and turret, and winches do the lifting of the load using hoist and wire. A small leak in the hydraulic line or problem in the winch motor may stall the complete loading/unloading operation.

Safety Devices: One cannot say a machinery is complete without any safety devices installed on it. The deck cargo crane is provided with an emergency stop, overload protection, hydraulic oil filter and level alarms, brakes etc. as safety devices.

The inspection and maintenance of the crane (including the base structure) are performed as per the maker’s instruction and also included in the Planned Maintenance System (PMS) of the ship.

To efficiently handle and maintain the ship’s crane, seafarer must know various tasks and essential points associated with crane components as explained above.

Some important tips are for efficient operation, and maintenance of cargo crane on ships are:

1.In most of the bulk carrier ship, the crane provided on ship’s deck is for both hook operation and grab operation. It is possible to have two different safe working loads for such cranes, i.e. one for hook and another for grab operation. Ensure the SWL is displayed clearly in the Jib and same is mentioned in the operator’s cabin to eliminate any confusion between two SWL.

2.When handling the crane with a load which is near to its rated capacity, ensure to operate with patience and extreme caution, especially when using lifting slings. If the rated capacity limiter activates, the crane boom will suddenly stop causing the load to swing or bounce.

3.During the stowed position, the hook of the hoist is clamped to a strong fixed point on deck. Ensure when lifting the boom/jib, it has been unhooked, and the jib is free of obstructions

4.Never operate the Crane Jib below its lower limit with a load on the hoist, which can lead to failure of the jib or slipping of wire from its drum.

5.Various limit switches are provided to restrict the movement of jib crane to its maximum positions. Most of the cranes are provided with a key to bypass the limit switch for the jib. The operator and chief officer must ensure the key is never left in the cabin of the crane once the operation is finished. The key should be operated only under chief officer’s supervision, and crane should be operated with utmost care.

6.Always check the base structure of the vessel before operating it for loosen foundation bolts and cracks in the structure. When the crane is operating at its maximum load, the base structure undergoes heavy stresses.

7.The base structure contains the rotational parts involving sheaves, bearings and slew rings etc. They should be timely inspected to determine any wear on the parts. All these moving parts and equipment must be lubricated correctly using the appropriate grease.

8.It has been reported in the past about the welding or other hot work carried by ship staff on crane structure or jib. Never carry out any modification or welding job on crane structure or jib without consulting the maker. It is a substantial load carrying machinery subjected to massive, fluctuating loads. The crane parts are often made of a high-tensile material, for which specialized welding and repairing procedures are needed. If the jib of the crane shows any damage, it has to be reported to the owner and maker for getting the recommended repair advice.

9.When performing welding on crane parts such as a jib, parts carrying wire ropes etc., it is recommended to disconnect the battery and switch off all the electronic control module and any other electronic components provided in the crane.

10.The most common failure related to the crane is the failure of wire ropes. The steel wire ropes must be lubricated to all its length and especially in the way of sheaves when the crane is in the stowed position. It is the responsibility of the Chief Officers to ensure all parts of the wire rope are regularly inspected and dressed with lubrication. Lack of lubrication may increase the rate of corrosion, leading to decrease in the elasticity, fractured strand, breakage of wire etc. The ancillary parts for carrying the cable such as pully, winch drum must be greased to eliminate any rough surface and friction.

11.The ship staff has to timely check the condition of the hydraulic oil. The most common reason for deck crane machinery failure is dirty hydraulic oil, leading to choking of filters. The oil should be sent to shore for analysis at prescribed intervals of time to get the detailed analysis of the system

12.The brakes being the critical safety arrangement for the crane, has to be inspected at regular intervals of time by checking the lining condition for its thickness. If disk brakes are provided, clearance must be checks and the record to be added to the PMS file.

13.Many times it has been observed onboard that the covers of the limit switch box or other electrical connections are kept open all the time for the ease of checking. Always shut the cover as it has a waterproofing arrangement which prevents switched from malfunctioning during rainy weather.

14.Hydraulic leaks are very common in all types of cranes, whether it is onboard deck cargo crane or a gantry crane in port. Never check the leaks using bare hands. Even a small hole will have pressurised hydraulic oil coming out as a fine mist will penetrate and damage the skin, and could do worse to human eyes. Always stop the operation, de-pressurise the line and then start the repair work.

Apart from the above maintenance and operating care, it is essential to follow the load test requirements which is done every five years by a competent representative of a classification society.