On January 15, 2026 (local time), the Red Sea Container Terminals (RSCT) at Sokhna Port, located at the southern entrance of the Suez Canal in Egypt, officially commenced operations.

The project is jointly invested in and operated by COSCO SHIPPING Ports, Hutchison Ports, and CMA Terminals. Egyptian Prime Minister Mostafa Madbouly, Vice Prime Minister and Minister of Transport and Industry Kamel Al-Wazir, and Walid Gamal El-Din, Chairman of the Suez Canal Economic Zone (SCZone), attended the ceremony alongside shareholders’ representatives including Zhu Tao, Chairman of COSCO SHIPPING Ports, marking the milestone.

Sokhna: A Strategic Gateway on a World-Class Corridor

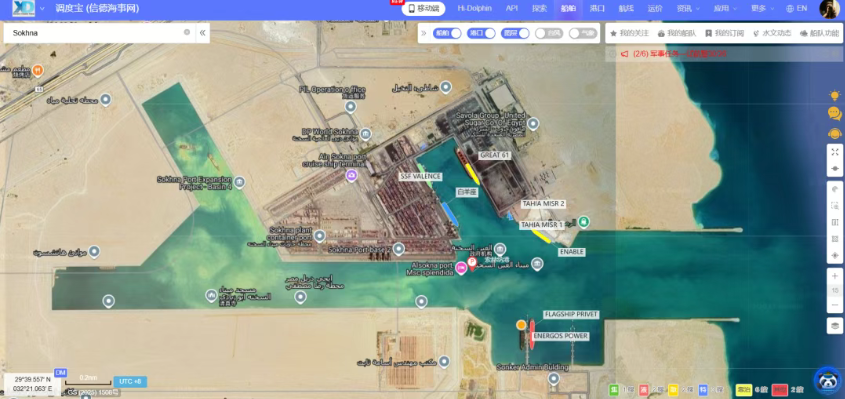

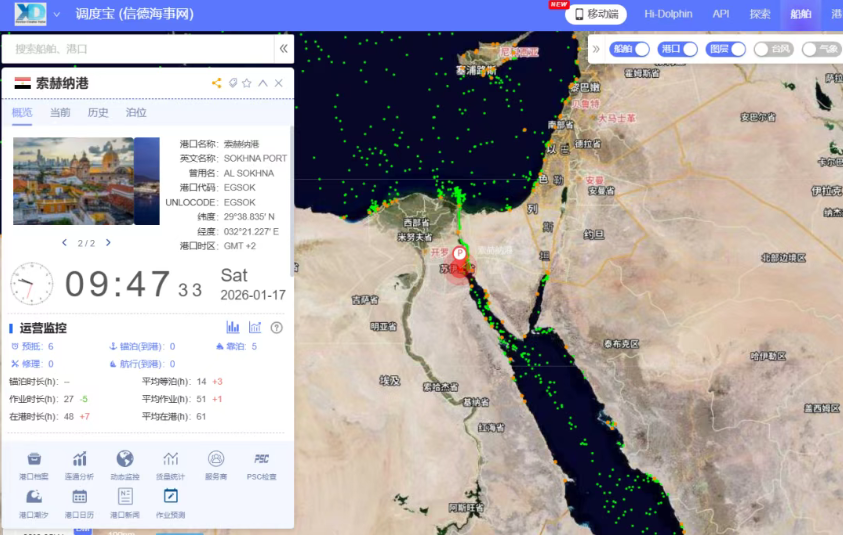

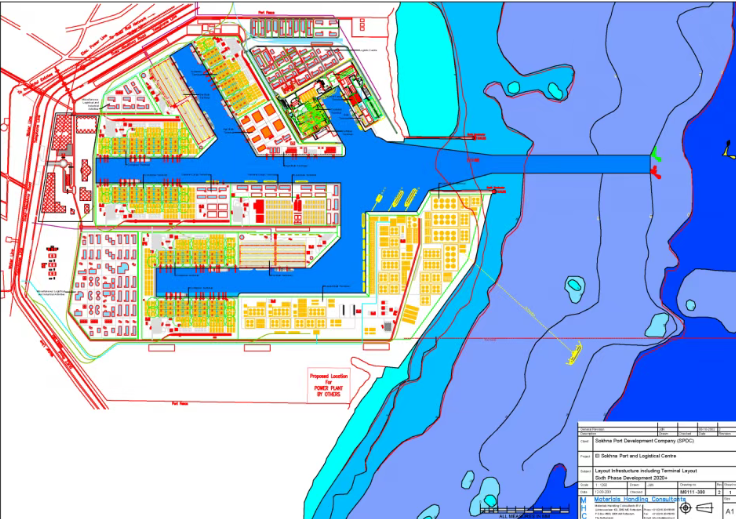

Sokhna Port is one of Egypt’s premier port zones. It sits at the southern entrance of the Suez Canal, around 120 km east of Cairo, adjacent to the Suez Northwest Economic Zone (SCZone), and at a key junction where the main East-West trade corridor overlaps with Egypt’s industrial belt. RSCT involves total investment of about USD 375 million. Phase I includes a 1,200-meter quay with an 18-meter water depth, and is designed for annual throughput of 1.7 million TEU. COSCO SHIPPING Ports holds a 25% stake.

This location means RSCT is not positioned as a standalone terminal, but as a corridor-oriented hub—serving global trunk routes, regional industrial clusters, and multimodal logistics organization. As shippers increasingly stress delivery certainty, inventory turnover, and risk redundancy, the value of a corridor is not only whether it can be used, but whether it can be used steadily, transferred quickly, and connected smoothly. Sokhna’s structural advantage lies in coupling maritime lanes with the port-adjacent industrial-logistics zone and regional road-rail networks.

Semi-Automation and Green Electrification: “Hard Tech” in the Service of Predictability

RSCT is positioned as a flagship infrastructure project under Egypt’s “Vision 2030,” and its start-up is presented as a marker of Egypt’s port-logistics sector entering a semi-automated era. Described as the first container terminal in Egypt to apply remote-controlled crane technology, RSCT is equipped with remote-controlled ship-to-shore (STS) cranes and automated yard gantry cranes, supported by advanced terminal operating systems (TOS) to drive more digitalized and precise workflows.

Its green configuration is also emphasized: the terminal deploys large-scale all-electric cargo-handling equipment, including electric trucks and electric reach stackers, to reduce its carbon footprint and respond to the global sustainability trend.

In Xinde Maritime News’ framing, these are not “equipment showcases,” but capability building around customer pain points. As supply-chain uncertainty rises, customers increasingly expect ports to perform more like industrial production lines: stable throughput, predictable efficiency, responsive exception handling, and traceable information. Semi-automation and digitalization aim to move operations from “experience-based and volatile” toward “process-based and controllable.” Electrification and green operations, meanwhile, offer customers a longer-term low-carbon corridor option as compliance and ESG thresholds continue to rise.

Linking with Regional—and Global—Hub Network

Xinde Maritime News understands that COSCO SHIPPING Ports has already established the Suez Canal Container Terminal (SCCT) at Port Said. With SCCT at the canal’s northern end and RSCT at the southern end, the launch of RSCT suggests that COSCO SHIPPING Ports has further completed and strengthened its port-logistics network around the Suez Canal. Together, the two terminals can provide a more flexible gateway set-up and redundancy for different route organization, cargo-flow directions, and customer needs.

More broadly, COSCO SHIPPING Ports has stated that the Sokhna terminal will be organically connected with its facilities and port-logistics services in surrounding regions and across its wider global network to form an integrated system, aimed at providing customers with more efficient and cost-effective services. In Xinde Maritime News’ view, this is where “network value” becomes visible: the more strategic the node and the more systematic the network, the more customers’ demand for predictability can be extended from a single terminal segment to a broader end-to-end experience.

COSCO SHIPPING Group: “Building Certainty into Supply-Chain Structures”

In recent years, the group has repeatedly highlighted an integrated “Shipping + Port + Logistics” service system—where shipping underpins transoceanic trunk legs, ports secure critical hub nodes, and logistics connects the hinterland and enables end-to-end delivery. RSCT represents an incremental capability build-up by the ports arm along a key corridor, and that capability enhancement is increasingly resonating with moves across other group business lines.

Over the past year, COSCO SHIPPING Specialized Carriers has continued to advance a system described as “linerization + nodal layout + localization.” Domestically, it set up East China and North China divisions to establish delivery organizations closer to key industrial clusters. On the product side, it pushed forward “three lines in parallel,” expanding its liner system from five routes to eight, emphasizing that stable frequency can turn “schedule uncertainty” into “predictability.” Overseas, it established a function-integrated, comprehensive supply-chain core node in Dammam, Saudi Arabia, to reinforce the “last mile” and accelerate its transition from a transport provider to a supply-chain partner. The company has also promoted integrated operations—covering global sales, capacity coordination, and supply-chain coordination—under an upgraded “3+4+N” global service architecture.

Please Contact Us at:

media@xindemarine.com