SOLAS II-I Reg. 3-8 "Towing and mooring equipment" was amended by the Maritime Safety Com- mittee MSC.102 in 2020 and enters into force on 1 January 2024. As a result, two new guidelines have been created: MSC.1/Circ.1619 and MSC.1/Circ.1620. Read more about the amended safe mooring requirements in this statutory news. Circ.1620, while MSC.1/Circ.1175 was revised.

To reduce serious and fatal accidents related to the handling of mooring lines or equipment used for mooring operation, the MSC introduced new requirements on the design, inspec- tion, and maintenance of mooring equipment (lines). The two guidelines on safe mooring are:

•The MSC.1/Circ.1619, Guidelines on the design of mooring arrangements and the selection of appropriate mooring equipment and fittings for safe mooring, which will affect new buildings

•The MSC.1/Circ.1620, Guidelines for inspection and maintenance of mooring equipment including lines, which will be a retroactive requirement and will therefore affect existing vessels

The latter guideline, MSC.1/Circ.1620, includes procedures for mooring operation, inspection and maintenance of moor- ing equipment and lines, identifying worn-out lines and tails, and replacement of mooring lines and tails. All ships need to comply with the retroactive statutory requirements, and DNV has issued RRs (retroactive requirement) for all ships. The RRs will affect existing ships, but the biggest impact will be for vessels built before 2007, since the approval of the associated hull support foundation of mooring fitting was not required at that time, and assignment of mooring fitting was probably not reviewed.

A list of the typical issues detected:

Applicable for all ships

1.Mooring operation procedure, inspection and maintenance plan were not available on board.

2.Wrong setting of mooring winch brake holding strength.

3.Selecting higher minimum breaking load (MBL) of mooring rope for replacement.

Applicable for ships built before 2007

4.The MBL of the mooring line was not in accordance with the recommended values in the corresponding approved equipment number in IACS Rec. 10; in many cases, a higher MBL rope was used.

5.The marked safe working load (SWL) of the mooring fitting was not consistent with the MBL of the mooring ropes.

6.The hull support foundation of the mooring fitting did not have sufficient capacity to withstand the design load or marked SWL.

The owner shall prepare documents listed in DNV's “Guidance for maintenance and inspection of mooring equipment”. This guideline corresponds to the new MSC.1/Circ.1620.

Early compliance statements can be requested through a remote survey. The occasional survey (SMO.O) to verify com- pliance with MSC.1/Circ.1620 is available through a remote survey request by including RR Ref. 1059a. More details can be found in DNV's

Compliance Planner, available to our customers in Fleet Status on Veracity.

An additional and voluntary class notation MO (qualifiers: D for newbuilding and IM for existing ships) will be offered for all ships. This notation class complies with the amended requirements in SOLAS II-I Reg.3-8 from 1 January 2023,and the two corresponding guidelines MSC.1/Circ.1619 and 1620.

Recommendations

We recommend our customers to consider early compliance with the new safe mooring requirements, especially for vessels which are scheduled to dry dock before 2024.

References

•SOLAS II-I Reg.3-8, Towing and mooring equipment

•MSC.1/Circ.1619, Guidelines on the design of mooring arrangements and the selection of appropriate mooring equipment and fittings for safe mooring

•MSC.1/Circ.1620, Guidelines for inspection and mainte- nance of mooring equipment including lines

•MSC.1/Circ.1175, Guidance on shipboard towing and mooring equipment

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Reporting Requirements for Foreign-flagged Ships En

Reporting Requirements for Foreign-flagged Ships En  Shipping Carriers Move to Prevent Deadly Charcoal F

Shipping Carriers Move to Prevent Deadly Charcoal F  KR, HD KSOE, HD HHI, KSS Line, and Liberian Registr

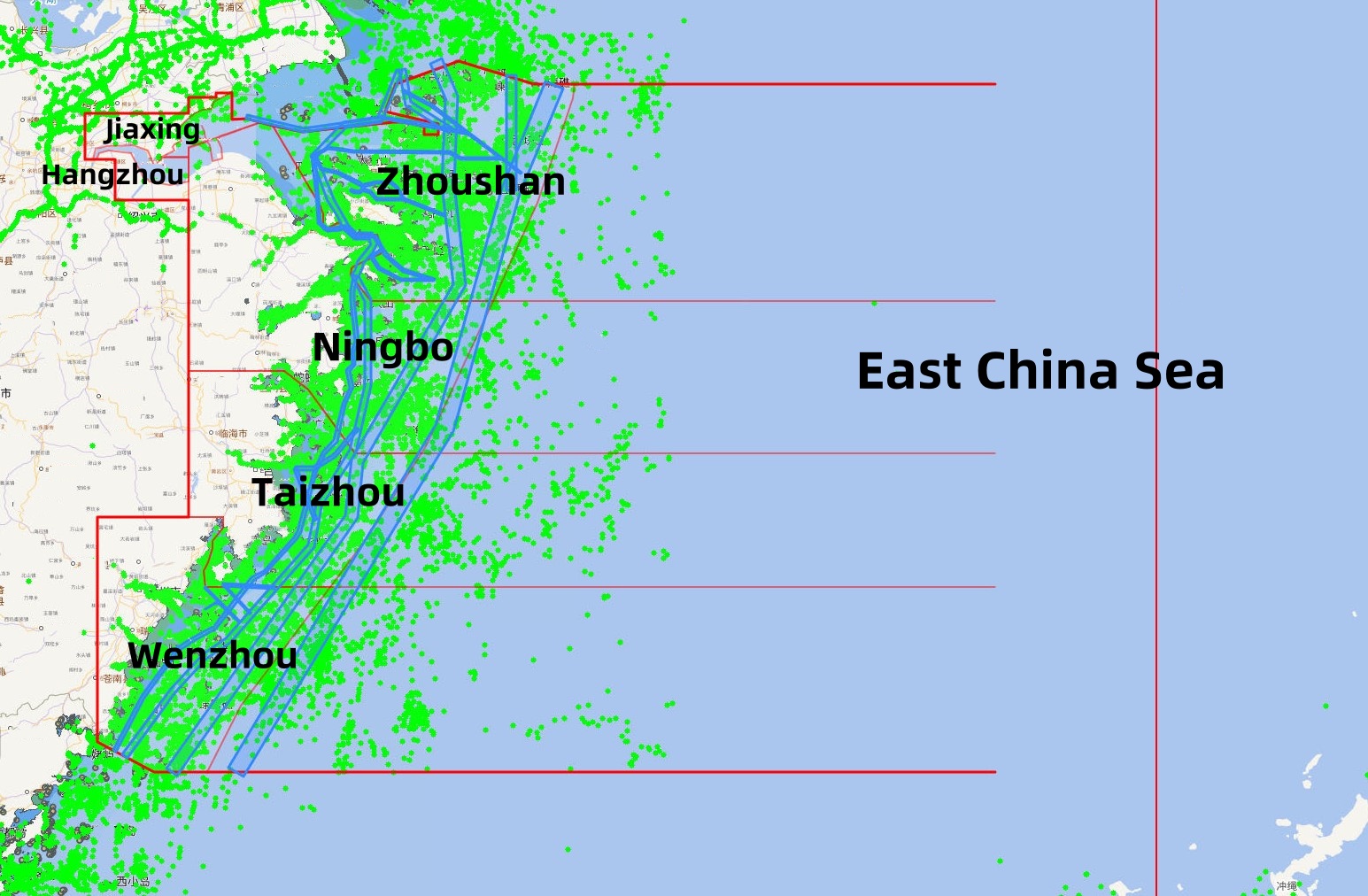

KR, HD KSOE, HD HHI, KSS Line, and Liberian Registr  Zhejiang Maritime Safety Administration Issues the “

Zhejiang Maritime Safety Administration Issues the “  RightShip Updates Age Trigger for Vessel Inspection

RightShip Updates Age Trigger for Vessel Inspection  KR Publishes Report on Safe Maritime Transport of E

KR Publishes Report on Safe Maritime Transport of E