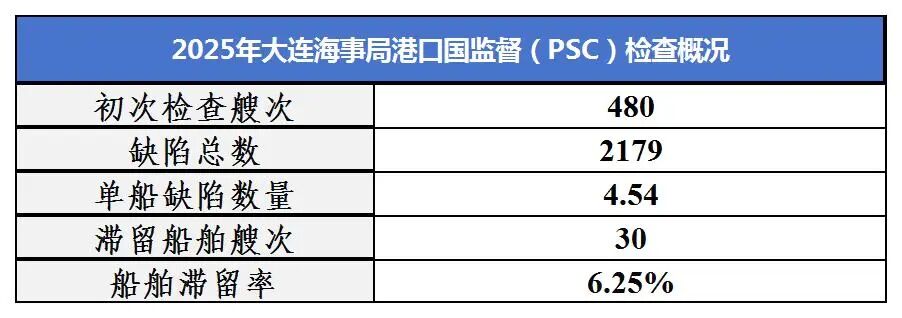

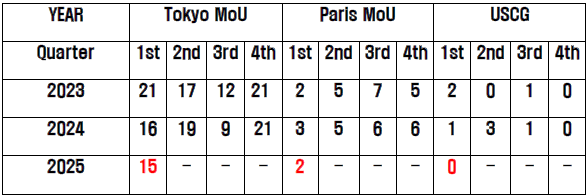

2025年第一季度PSC检查报告刚刚更新。跟2024年第一季度同期相比,滞留缺陷有所降低,TOKYO MOU依旧是滞留最多的,USCG2025年还没有下手。

1 通用滞留缺陷TOP10

1、Lifeboat davit, winch, release gear and block assembly

救生艇吊艇架、绞车、释放装置和滑轮组件

2、Engine starting of lifeboat and rescue boat

救生艇和救助艇的发动机启动

3、Air pipe and head

通风管和通风帽

4、Hatch cover and its attachments

舱口盖及其附件

5、GMDSS equipment

全球海上遇险与安全系统(GMDSS)设备

6、Hatch coaming and its attachments

舱口围板及其附件

7、Ventilator and E/R fire damper

通风装置和机舱防火挡板

8、Emergency fire pump, Emergency G/E

应急消防泵、应急发电机

9、Oil filtering equipment/Oily water separator & Sewage System

滤油设备 / 油水分离器及污水系统

10、Crew familiarization, ISM implementation

船员熟悉程度、《国际安全管理规则》(ISM)的实施情况

对 10 项主要可导致滞留的缺陷,需开展加强版定期检查和审核。一旦船舶在完成检查或审核后不久,因 PSC 检查被滞留,需提供相应证明材料。

同时,船上防止海洋污染的设备必须正确安装与维护,发现机舱漏油要立即采取措施。对于 PSC 主要谅解备忘录区域内船舶的消防安全、应急设备和救生艇筏的重大缺陷,要进行全面检查,并依据法规检查 ISM 和 MLC 相关事项。

船长和船务主管肩负即时报告责任,定期维护时发现缺陷,要立即向港口当局报告;船舶被滞留时,需马上向船级社报告,说明滞留相关事宜。

脱船级期间的 PSC 整改历史是检查重点,需确保之前 PSC 报告中的缺陷状况清晰。

对船龄较大,或在东京、巴黎备忘录及美国海岸警卫队管辖区域内维护状况差的船舶,会实施强化 PSC 检查。这类船舶一旦发现重大缺陷或大量问题,可能被迅速滞留;即便存在众多轻微缺陷,也可能因 ISM 规则被滞留。

船员对应急响应演习的熟悉程度,特别是在日本地区,是 PSC 检查的重要内容。

2 巴黎备忘录Paris MoU

可导致滞留的缺陷

- 消防安全

- Fire Dampers of E/R supplier fans not workings & duct distortion

机舱送风机的防火挡板无法工作,且管道变形

- Fire Doors – upper deck entrance to staircase distortion)

防火门——上甲板通往楼梯间的入口处防火门变形

- Emergency fire pump found inoperative during test

测试时发现应急消防泵无法运行

- A-class fire door in galley fixed to open

厨房的A级防火门被固定为常开状态

- Water mist system defective

水雾系统故障

- Some fire doors defective and not closed completely

部分防火门存在故障,无法完全关闭

- Several self-closing valves for sounding pipes and for level indicators blocked in open position

多个测深管和液位指示器的自闭阀被卡处于开启状态

- Oil leakage from main engine oil cooler through damaged gaskets

主机机油冷却器因垫片损坏而漏油

- Main fire line on main deck inoperative (frozen)

主甲板的主消防管路无法使用(已冻结)

- Leakage of fire hose and corrosion of fire main line

消防水带漏水,消防主管路腐蚀

- Clogged Paint room sprinkle nozzles failed to activate

油漆间喷淋喷嘴堵塞,无法启动

- Full of oil mixture in engine room bilge well

机舱污水井内充满混合油污

- Air leaking from SCBA

自给式呼吸器(SCBA)漏气

- Malfunction of Quick Closing Valve for fuel oil tank

燃油舱速闭阀故障

- Fire detection system in cargo holds defective

货舱火灾探测系统故障

- Fixed CO₂ bottle hose loosening

固定二氧化碳气瓶的软管松动

- Galley Exhaust Trunk Oily and Dirty(Risk of Fire)

厨房排气管道油污脏污(存在火灾风险)

- Quick closing valve malfunction

速闭阀故障

- Auto closing valves of FO tank level gauge were fixed in open position

燃油舱液位计的自动关闭阀被固定在开启位置

- Escape routes of Rope Store were not secured due to obstacle

缆绳储存间的逃生通道因障碍物无法确保畅通

- Not familiar with Fire Drills

不熟悉消防演习流程

- Insufficient check of Fire Man’s Outfit during Fire Drills(Ignoring Air leakage in Mask and air low pressure alarm of air bottle)

消防演习时对消防员装备检查不足(忽略了面罩漏气和气瓶低压报警问题 )

- 国际安全管理体系(ISM)

- ISM detainable deficiency on the basis of many deficiencies

基于多项缺陷而构成的可导致滞留的ISM缺陷

- Collision due to non-compliance with COLREG

因未遵守《国际海上避碰规则》(COLREG)而发生碰撞

- Fire drill not satisfactory

消防演习不达标

- Crew not familiar with working language

船员不熟悉工作语言

- Crew not familiar with fixed CO2 system

船员不熟悉固定式二氧化碳系统

- Crew not familiar with RADAR operation and emergency steering

船员不熟悉雷达操作和应急操舵

- Inappropriate implementation of enclosed space procedures

封闭空间作业程序执行不当

- Officers unable to demonstrate operation of free fall lifeboat

高级船员无法演示自由降落救生艇的操作

- SMS implementation failure

安全管理体系(SMS)实施失败

- Crew unfamiliar with operation of machinery and position of equipment on board

船员不熟悉船上机械设备的操作以及设备的位置

- No records of lifeboat operation

无救生艇操作记录

- 国际船舶和港口设施保安规则(ISPS)

- Outdated CSR on board

船上的船舶保安计划(CSR)已过时

- 海事劳工公约(MLC)(工作和生活条件)

- Accommodation heating systems

居住舱室供暖系统

- Toilets flushing system in the accommodation not working correctly

居住舱室的厕所冲水系统无法正常工作

- Accommodation not in cleanliness

居住舱室不清洁

- All crew members' wages not paid in full and at monthly intervals

未全额且按月支付所有船员的工资

- Total lack of fresh vegetables and fruit. Rotten cabbage visible in veggie store

完全缺乏新鲜蔬菜和水果。在蔬菜储存间可见腐烂的卷心菜

- Water in galley is very dirty and basin clogged, no usable hot water available for handwash and safe preparation of meals

厨房的水非常脏,水槽堵塞,没有可用的热水用于洗手和安全准备餐食

- Parasite/pest detection (galley floor and rotting storage room)

发现寄生虫/害虫(厨房地板和腐烂的储存间)

- Risk of electric shock due to wires falling out in the meat storage room

肉类储存间电线外露,存在触电风险

- SEA(Seafarer employment agreement) expired, over maximum period of shipboard service for seafarers

海员就业协议(SEA)已过期,超过了海员在船服务的最长期限

- Two(2) crewmembers on board with illegal extension/to more than allowed by CBA

船上有两名船员的服务期限非法延长,超过了集体谈判协议(CBA)所允许的期限

- Two(2) ratings not complying with STCW convention

两名普通船员不符合《海员培训、发证和值班标准国际公约》(STCW公约)

- Air conditioner malfunction (spare part not on board)

空调故障(船上无备件)

- After drydock, garbage and spare parts stowed all along the main deck

进干船坞后,垃圾和备件沿主甲板随意堆放

- Medical Oxygen are not ready to use immediately

医用氧气无法立即投入使用

- Quantity and position of Laundry equipment is not adequate

洗衣设备的数量和摆放位置不恰当

- Due to Black out, all toilet are not available and living condition is under standard (no water, heating)

由于停电,所有厕所无法使用,生活条件不达标(无水、无供暖)

- Insulation of High Temperature parts in engine room not in good condition

机舱内高温部件的隔热情况不佳

- Risk of work in crane (bad visibility)

起重机作业存在风险(能见度差)

- 救生设备

- Lifeboat Engine not starting

救生艇发动机无法启动

- Lifeboats not lowered and maneuvered into the water

救生艇未降放入水并进行操纵

- Lifeboats Hull Crack (Stacked FRPs are separated partially)

救生艇船体裂缝(层叠的玻璃纤维增强塑料部分分离)

- Rescue boat and life raft defective

救助艇和救生筏有缺陷

- Life raft expired

救生筏已过期

- Garbage interfering the operation of port liferaft

垃圾妨碍了港口救生筏的操作

- Magnetic compass in lifeboat defective

救生艇内的磁罗经有缺陷

- Rescue boat launching davit hydraulic leaks and pressure gauge inoperative

救助艇吊艇架液压系统泄漏,压力表无法工作

- Rescue boat davit failed to slew

救助艇吊艇架无法回转

- Breathing apparatus set back rack broken

呼吸器存放架损坏

- Several EEBDs with insufficient air pressure

多个紧急逃生呼吸装置(EEBD)气压不足

- Liferaft ladders P and S rope rutten in splice

救生筏左右舷梯子的绳索在拼接处腐烂

- Liferaft is stored in another location

救生筏存放位置不当

- Liferaft is not properly secured

救生筏未妥善固定

- Malfunction of emergency light in way of rescue boat launching area

救助艇放艇区域的应急灯故障

- Malfunction of light Life Buoy

带灯救生圈故障

- Rescue boat damaged due to contact during drills

救助艇在演习过程中因碰撞而损坏

- Automatic release of lashing during lifeboat lowering is not possible

救生艇降落时无法自动释放系固装置

- 防污染

- Deck full of oil pollution hazards

甲板上充满油污污染隐患

- Insufficient procedure for changeover when entering SECA (Aux. Engines and boiler)

进入特殊排放控制区(SECA)时,辅机和锅炉的转换程序不完善

- EGCS parameter value remains unchanged within emission control area

废气清洁系统(EGCS)参数值在排放控制区内未发生变化

- Sewage treatment plant not working properly

污水处理装置无法正常工作

- Dosing pump of Sewage treatment plant not working

污水处理装置的加药泵无法工作

- OWS sampling pipe closed, and circulated with fresh water only to indicate 0ppm on oil content Monitor

油水分离器(OWS)采样管关闭,仅用淡水循环以使油分浓度监测仪显示为0ppm

- Eng. Room Bilge High water level alarm inoperative

机舱污水井高水位报警装置无法工作

- Oily Water Separator inoperative and found some leakage

油水分离器无法工作,且发现有泄漏现象

- Hatch cover hydraulic cylinder found leaking

舱口盖液压缸发现泄漏

- OWS solenoid valve inoperative

油水分离器电磁阀无法工作

- Retention indicated in Oil record book for M/E Scav. Air box drain tank is; 0.2m3. Retention really found on board in drain tank is; 0.12m3. 0.08m3 missing

主机扫气箱泄放舱的油类记录簿中记录的留存数量为0.2立方米,而船上实际在泄放舱中发现的留存数量为0.12立方米,缺少0.08立方米

- Full of Residual tank(Sludge tank) & bilge collecting tank(Not correctly filled out on oil record book)

残油舱(污泥舱)和污水收集舱已满(油类记录簿填写不正确)

- Many casks with sludge oil found on board

在船上发现许多装有污油的桶

- Oil spill during bunkering (Not in accordance with bunkering procedure)

加油过程中发生溢油(未按照加油程序操作)

- NOx Technical File not on board

船上无氮氧化物(NOx)技术文件

- BWTS inoperable and three(3) alarms can not be reset

压载水管理系统(BWTS)无法运行,且三个报警无法复位

- Holes in Burning chamber of incinerator and insulation materials are partially missing

焚烧炉燃烧室有孔洞,隔热材料部分缺失

- 船体结构(ILL)

- Side shell crack

船侧外板裂缝

- Manhole from engine room to bilge keel space in open

从机舱到舭龙骨空间的人孔处于开启状态

- Hatch coaming bracket crack

舱口围板托架裂缝

- Air vent head damaged and seized with metallic float disc broken and seized rubber seal detached, Natural ventilator (mushroom type) holed and patched temporally, Gooseneck air vent closing devices missing

通风头损坏且卡住,金属浮盘破裂,卡住的橡胶密封件脱落,自然通风筒(蘑菇型)有孔洞并临时修补,鹅颈式通风筒关闭装置缺失

- Hatch cover cleat missing

舱口盖系固扣缺失

- Missing hinge for cargo hold ventilator damper and poor condition of closing device

货舱通风挡板铰链缺失,关闭装置状况不佳

- 证书和文件

- Civil liability for bunker oil pollution damage certification is not valid (Only photocopy)

燃油污染损害民事责任证书无效(仅有复印件)

- CSR Document missing

船舶保安计划(CSR)文件缺失

- Oily water discharged illegally (Cert. not valid)

非法排放含油污水(证书无效)

- Flag endorsement missing for 2/O, 3/O and C/E

二副、三副和轮机长的船旗国签注缺失

- Medical certificate expired

医疗证书过期

- Captain not holding GMDSS General Operator certificate (GOC)

船长未持有全球海上遇险与安全系统(GMDSS)通用操作员证书(GOC)

- No Safety Management Certificate (SMC) on board

船上无安全管理证书(SMC)

- SOLAS Training Manual and Fire Fighting Manual is different from ship details

《国际海上人命安全公约》(SOLAS)培训手册和消防手册与船舶实际情况不符

- SEAs(Seafarers’ employment agreement) of all crew members are not original and not signed by the ship owner(Stamp only)

所有船员的海员就业协议(SEA)不是原件,且未经船东签字(仅有盖章)

- Interim MLC certificates were issued two times consecutively

连续两次发放海事劳工公约(MLC)临时证书

- IBWM certificate is not valid. (IOPP renewal was conducted under permission of Flag with extension of BWTS of installation)

国际压载水管理证书无效。(国际防止油污证书(IOPP)在船旗国许可下进行了换证,同时延长了压载水管理系统的安装期限)

- IMO Symbol partially missed

国际海事组织(IMO)标志部分缺失

- Unable to confirm authenticity of IOPP electronic certificate

无法确认国际防止油污证书(IOPP)电子证书的真实性

- 航行安全

- VDR is inoperative

船舶数据记录仪(VDR)无法工作

- VDR statement of compliance was not on board

船上无船舶数据记录仪符合声明

- Several navigation lights damaged and inoperative

多个航行灯损坏且无法工作

- ECDIS not in use up to date (ENC outdated) and malfunction

电子海图显示与信息系统(ECDIS)目前未使用(电子海图(ENC)过期)且出现故障

- Paper charts for intended voyage not up to date

计划航行的纸质海图未更新

- MF/HF and VHF DSC not operational

中高频(MF/HF)和甚高频(VHF)数字选择性呼叫(DSC)设备无法工作

- No charts and nautical publications available

无海图和航海出版物

- Bridge found one window of different thickness(much less)

驾驶台发现一扇窗户厚度不同(薄很多)

- Whistle inoperative

汽笛无法工作

- Missing of Ship’s bell

船钟缺失

- AIS signal weak

船舶自动识别系统(AIS)信号弱

- GPS position information error

全球定位系统(GPS)位置信息错误

- Gyro repeater of port/stbd side is not synchronized with bridge Gyro Compass

左/右舷陀螺罗经复示器与驾驶台主陀螺罗经不同步

- INMARSAT C fault

国际海事卫星组织C站(INMARSAT C)故障

- MH/HF antenna damaged

中高频天线损坏

- Working language recorded on ship’s official log book are English and Vietnamese

船舶正式航海日志记录的工作语言为英语和越南语

- Poor Communication between crew members

船员之间沟通不畅

- 其他

- Several steam and water leakages on deck steam pipes

甲板蒸汽管道有多处蒸汽和水泄漏

- Emergency exit from engine room blocked from inside by steel plate

机舱应急出口从内部被钢板堵塞

- Insufficient ventilation of cargo holds before entering a port (excess of LEL limitation)

进港前货舱通风不足(超过了爆炸下限(LEL)限制)

- No corrective action taken against deficiencies identified during the last PSC inspection

对上一次港口国监督(PSC)检查中发现的缺陷未采取纠正措施

- Several nuts and bolts for void space manholes in Bosun store missing

水手长仓库内空舱人孔的多个螺母和螺栓缺失

- Boiler water level sight glass malfunction

锅炉水位视镜故障

- Incinerator not properly maintained (diesel oil solenoid valve defective)

焚烧炉未得到妥善维护(柴油电磁阀有缺陷)

- Gangway accommodation ladder unsafe (broken stanchion)

舷梯和居住舱室梯子不安全(支柱损坏)

- Ballast water exchange not performed before entering the port

进港前未进行压载水更换

- Two sailing directions not regularly updated

两份航行指南未定期更新

- Emergency lights not working properly

应急灯无法正常工作

- Several manholes for ballast water tanks on portside and starboard side not properly closed/ Missing nuts/Damaged gaskets

左舷和右舷的多个压载水舱人孔未妥善关闭/螺母缺失/垫片损坏

- Improper modification on SWBD

开关板(SWBD)改装不当

- E/R direct bilge valve not able to open

机舱直接污水阀无法打开

- Bilge alarm floaters in C/H functionally damaged

货舱污水报警浮球功能损坏

- EPIRB test inoperative, periodical GMDSS log not on board

紧急位置指示无线电信标(EPIRB)测试无法进行,船上无定期的全球海上遇险与安全系统(GMDSS)日志

- Loss of seaworthiness due to flooding of steering gear room(water-tight door was open)

因舵机房进水(水密门开启)导致船舶丧失适航性

- Black out due to lack of fuel and failed to recover the power

因燃油不足导致停电,且未能恢复供电

- Install a imitation filter on the oil mist detector of the main engine

在主机油雾探测器上安装了仿冒滤芯

- Switch board cable of OWS not properly secured, cable connection part not in good condition

油水分离器(OWS)开关板电缆未妥善固定,电缆连接部分状况不佳

b) 需彻底检查的项目

- 消防安全

- Operation of em’cy fire pump and leak check(If it can be run in 5 minutes without any leakage, required minimum pressure of suction: -500mmHg, discharge: 3kg/c㎡)

应急消防泵的运行情况及泄漏检查(若能在5分钟内运行且无任何泄漏,要求最低吸入压力:-500毫米汞柱,排出压力:3公斤/平方厘米)

- Function and contact condition of E/R funnel damper

机舱烟囱挡板的功能及接触状况

- Condition of Fireman’s outfit

消防员装备的状况

- Closing condition of A-class fire door

A级防火门的关闭状况

- Fire doors in normal operation

防火门的正常运行情况

- Installation of insulation for heat surface

受热表面的隔热装置安装情况

- Enough ventilation of cargo holds before entering a port

进港前货舱的充分通风情况

- Check operation of water mist system

检查水雾系统的运行情况

- Check of breathing apparatus and its attachment

检查呼吸器及其附件

- Self-closing valves for sounding pipes and for level indicators

测深管和液位指示器的自闭阀

- Operation and maintenance of main engine oil cooler

主机机油冷却器的运行和维护情况

- Sprinkler nozzles in normal working condition without blockage of deposits in the nozzles

喷淋喷嘴处于正常工作状态,且喷嘴内无沉积物堵塞

- 国际安全管理体系(ISM)

- Implementation of Fire and Abandon ship Drill and record

(See attached Check point of Fire and Abandon ship Drill in UK)

消防和弃船演习的实施情况及记录

(见所附英国消防和弃船演习检查要点)

- Black out test (simulation test) and crews’ familiarity with it

停电测试(模拟测试)以及船员对该测试的熟悉程度

- Crews’ familiarity with the operation of CO2 system (delay time, bottle quantity, etc.)

船员对二氧化碳系统操作的熟悉程度(延迟时间、气瓶数量等)

- PSCO emphasizes implementation of ISM and checks real-time NIR database

港口国监督检查官(PSCO)强调国际安全管理体系(ISM)的实施情况,并检查实时近红外(NIR)数据库

- Drill records for emergency response

应急响应演习记录

- SMS on board properly implemented

船上安全管理体系(SMS)得到妥善实施

- Crew familiarization with machinery and position of equipment on board

船员对船上机械设备及设备位置的熟悉程度

- Correspondence and familiarization of SOLAS training manual and equipment on board

《国际海上人命安全公约》(SOLAS)培训手册与船上设备的一致性及船员对其的熟悉程度

- Check effectiveness of emergency drills and familiarity related to responsible equipment/ installation/appliances and system

检查应急演习的有效性以及船员对所负责设备/装置/器具和系统的熟悉程度

- Crew familiarization with lifeboat operation

船员对救生艇操作的熟悉程度

- Compliance of procedures for enclosed space entry

封闭空间进入程序的合规性

- Check compliance of COLREG of duty officers

检查值班驾驶员对《国际海上避碰规则》(COLREG)的遵守情况

- 海事劳工公约(MLC)(工作和生活条件)

- Crews protection (safety devices)

船员保护(安全装置)

- Crew’s including captain and C/E working hour and resting hour record

包括船长和轮机长在内的船员工作时间和休息时间记录

- Crew’s wage and Seafarer Employment Agreement (2024 CIC Items)

船员工资及海员就业协议(2024年集中检查项目(CIC))

- Toilet operation in accommodation

居住舱室中厕所的运行情况

- Accommodation cleanness

居住舱室的清洁状况

- Wages paid regularly and in full accordance with seafarer’s employment agreement(SEA)

根据海员就业协议(SEA)定期且全额支付工资

- Period of seafarer’s contract

海员合同期限

- Expiry date of medicine

药品的有效期

- 救生设备

- Immediate start of em’cy equipment under very cold weather

(Starting of em’cy generator engine & lifeboat engine, etc.)

在极寒天气下应急设备的即时启动情况(应急发电机发动机及救生艇发动机等的启动情况)

- Magnetic compass in lifeboat

救生艇内的磁罗经

- Hydraulic system in launching appliance for rescue boat

救助艇释放装置的液压系统

- Condition of rescue boat and liferaft

救助艇和救生筏的状况

- Navigation and radio equipment in good working condition for immediate use

航行和无线电设备处于良好工作状态,可立即投入使用

- EEBDs with sufficient air pressure and good working condition

紧急逃生呼吸装置(EEBD)气压充足且工作状态良好

- 防污染

- Operation of sewage treatment plant

污水处理装置的运行情况

- Inspection related to SOx emission (bunker notes, sampling log book, bunker change procedure)

与硫氧化物(SOx)排放相关的检查(加油单、采样日志、加油转换程序)

- Operation of quick closing valve (including em’cy generator DO tank)

速闭阀的运行情况(包括应急发电机柴油舱)

- Control of garbage (garbage record, galley and toilet condition etc.)

垃圾管理(垃圾记录、厨房和厕所状况等)

- Changing over fuel oil with Sulphur below 1.0% before entering into SECA area

在进入特殊排放控制区(SECA)前更换为硫含量低于1.0%的燃油

- Procedures for fuel changeover when entering SECA

进入特殊排放控制区(SECA)时的燃油转换程序

- Function of oily water separator and 15ppm alarm check (oil check inside discharge pipe and check for proper record of oil record book)

油水分离器的功能及15ppm报警检查(检查排放管内的含油量并检查油类记录簿的正确记录情况)

- High water level alarm(Eng. room)

机舱高水位报警装置

- Hatch cover hydraulic cylinder in good working condition

舱口盖液压缸工作状态良好

- Oily Water Separator (OWS) in proper working condition

油水分离器(OWS)处于正常工作状态

- 船体结构(ILL)

- Condition of structure (hatch cover cleat, air vent head)(hammering test)

结构状况(舱口盖系固扣、通风头)(锤击测试)

- Function of water ingress system and de-watering system

进水系统和排水系统的功能

- Manhole properly secured, closed

人孔妥善固定、关闭

-证书和文件

- Each Certificate (ESP File) and valid crew’s license

各类证书(等效安全证书(ESP)文件)及有效的船员证书

- Valid Medical Certificate

有效的医疗证书

- 航行安全

- VDR function and random alarm test and normal condition check after reset

船舶数据记录仪(VDR)的功能、随机报警测试以及复位后的正常状况检查

- Navigation plan (berth to berth) and up-to-date notice to mariner, chart and publication

航行计划(泊位到泊位)以及最新的航海通告、海图和航海出版物

- Function of GMDSS (DC Power) and familiarity with GMDSS equipment

全球海上遇险与安全系统(GMDSS)(直流电)的功能以及船员对GMDSS设备的熟悉程度

- Check condition of navigation lights

检查航行灯的状况

- Check ECDIS/ENC in use up to date

检查电子海图显示与信息系统(ECDIS)/电子海图(ENC)是否为最新可用状态

- 其他

- Ten (10) major detainable deficiencies and overall inspection

十项主要可导致滞留的缺陷及全面检查

- Extended inspection for bulk carrier more than 15 years

对船龄超过15年的散货船进行扩展检查

- Any obstacles to interrupt safety escape from emergency escape route from E/R

机舱应急逃生路线上是否存在妨碍安全逃生的障碍物

- Corrosive condition of Gangway

舷梯的腐蚀状况

- Engine room and S/G room cleanses (connections for piping system, oily insulation for piping, around D/G fuel pump, purifier room floor.

机舱和辅机间的清洁情况(管道系统连接部位、管道的油污隔热情况、辅机燃油泵周围、分油机间地面)

- Boiler water level sight glass in normal condition

锅炉水位视镜处于正常状态

- Incinerator properly maintained and in good working condition

焚烧炉得到妥善维护且工作状态良好

- Em'cy lights in good working condition

应急灯工作状态良好

未完待续~(USCG和TOKYO MOU将在后续更新)

信德海事安全综合报道

资讯

活动

航情

招聘

专栏

视频

专题

图片

领航者

资料库

ENGLISH