36条坞修前准备工作 助您轻松坞修

船厂坞修是一项繁琐而细致的工作,在进坞之前做好准备才能忙而不乱得心应手 这里总结了三十六条内容供同行参考

1.arrange meeting room (ship office or Ballast water control RM will be good option if possible or gym. RM )with copy machine, fridge, hot water ,coffee, tea, sugar, chairs etc on Ballast control room if possible.

首先准备一个合适的会议室,因为每天早晨都会和船厂各个部门碰头当天的工作安排和上一个工作日需要协调的问题

2.check and prepare all relevant drawings/plan for dry-dock (middle section, shell expansion drawing, docking plan, general arrangement, piping, framing ,anchor chain, rudder, propeller, aft seal/stern tube ,deck machine etc) ,which must be ready for use upon arrival at s/y.

准备图纸并且熟悉图纸

3.remove all movable items/equipment inside of lifeboat and lock the door ,which to be done before arrival at shipyard.

救生艇里面的所有仪器设备取出并且给救生艇上锁

4.remove all valuable items from deck and engine room: lifebouys, life raft , fire hose, brass nozzles, butterfly bolts and studs(brass material) for booby hatch covers ,brass covers for sounding pipe /air connection etc. and keep same in store with pad locks, which to be done before arrival at shipyard.

甲板机舱所有便携的设备,特别各种铜制品入库

5.prepare filters for A/C suction and engine room ventilation suction.

准备一些滤网,船厂粉尘比较大

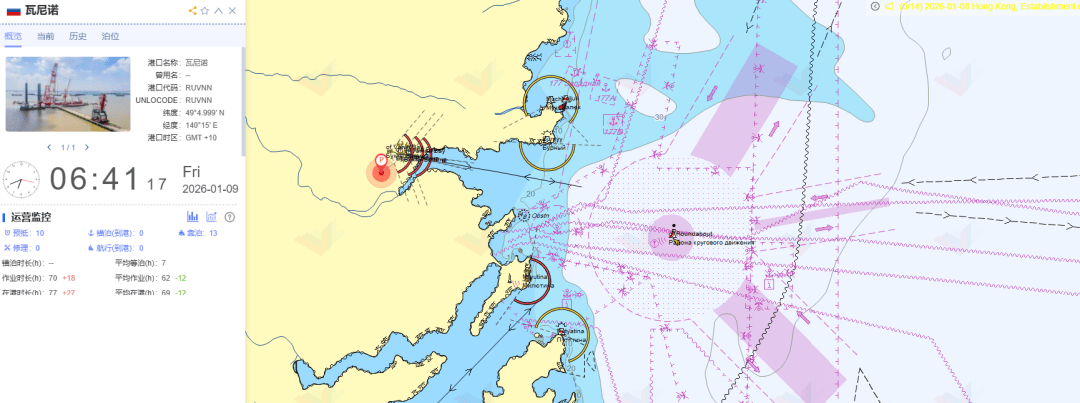

6.arrive in shipyard with minimum safe ballast water pls strictly follow agent guidance for ship’s draft from shipyard anchorage to shipyard terminal.

进船厂前 最好以保证安全的最少压载水 因为需要打开各个舱室的道门盖

7.find and check original connections for cooling water of provision machine, ECR air condition / acc. AC /shore power, additionally find where can be safely connected the compressed air for deck and E/R service. Most probably our ship will use shore power once vsl alongside.

到达船厂会换岸电和岸上冷却水提前熟悉接口位置,并且把长时间未使用过的阀门做个保养

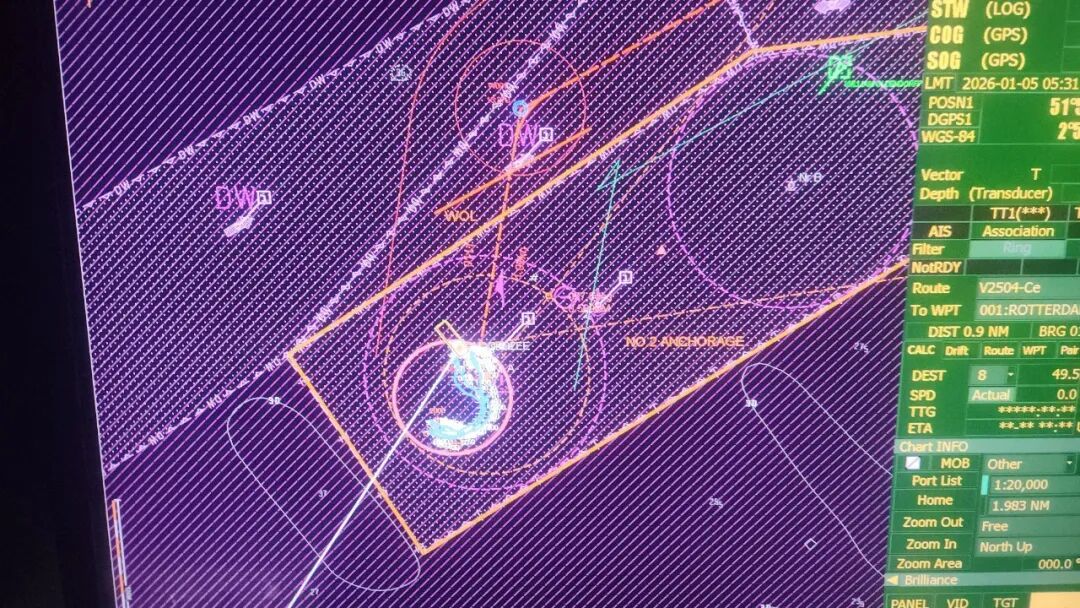

8.For safe of good order pls check/revert what is the draft details if all ballast water including FPT&APT pump out as all ballast water tanks to be carried out close up survey, FYI, normally shore power capacity is not sufficient for ballast water pump running at s/y.

确认所有压载水排空需要多长时间,船厂岸电一般不能保证压载泵正常运行

9.unbolts(remain few pcs for safety only)/open (if possible) manholes if possible : chain lockers, rudder trunk, TST on main deck after vsl depart from last disport.

把各个需要的人孔提前打开,在保证安全的前提下保留最少的螺丝

10.All vent heads on deck: one side cover to be opened if possible and remain two studs for easy opening.

打开通风的螺丝一般保留2个很方便的打开以备检查

11.plug and cement all scuppers on main deck except two(ps/stbd aft) before arrived at s/y..

甲板落水空 一般用水泥加破布塞紧,直保留生活区附近左右各一个

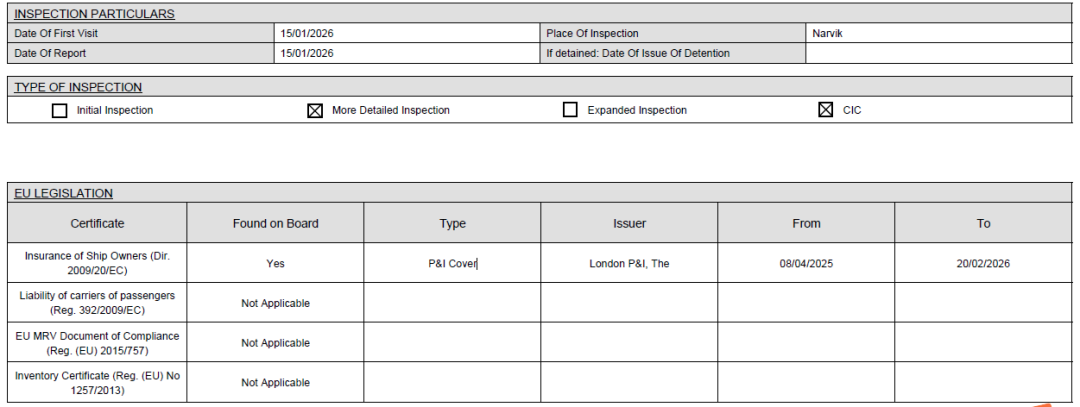

12.check survey status/certificates , if some of them due pls prepare list.

所有需要更新的证书准备好清单

13.After departure from disport , pls mark pipes /valves with red clour paint in engine room for repair / renewal(check what spare v/vs /rubber seats are on board especially sea connections /overboard v/vs/ballast water v/vs).

需要更换的阀和管路 做好码克

14.pls check whether all required spare parts/ material/equipment for dry-dock is available on board or ordered.

确认一下需要的备件船上是否有了 如果没有提前定备件

15.Pls advise what is the min. Draft when propeller is 100% submerged.

螺旋桨完全浸没的吃水

16.Deck and All c/holds to be cleaned if time is sufficient , as for cargo residues , same can leave on tanktop ,without any problem .

一般进船厂前需要在卸完货后清扫货舱 不要求太干净 但是不能影响船厂工作

17.If possible pls dispose all bilge /oily sludge at last disch port and keep min. Quantity of bilge water & oil sludge o/board upon arrival at s/y.

尽可能最少量的污油水进船厂 处理费用太高

18.Provision crane and E/R overhead crane has to be checked /tested and to ensure all are in order as both crane will be very busy at SY.

船上吊机测试保养处于随时可用状态 船厂吊货机市场价 一次600块

19.All h/covers to be opened after all protection rails on cover tops erected by SY, same will inform you by attending Supt.

根据要求第一时间打开舱盖

20.All stores in E/R and on Deck to be locked properly including workshop and spare lockers , ship side just provide various special tools to SY workers only.

各种工具收好 各个物料间上锁

21.- re mooring winch rendering test

Pls check and confirm full set of tools are available onoard and the hydr oil pump/jack is in order.

测试缆车BREAK HOLDING CAPCITY 的设备要提前准备好 一般船厂会测试并且出证书

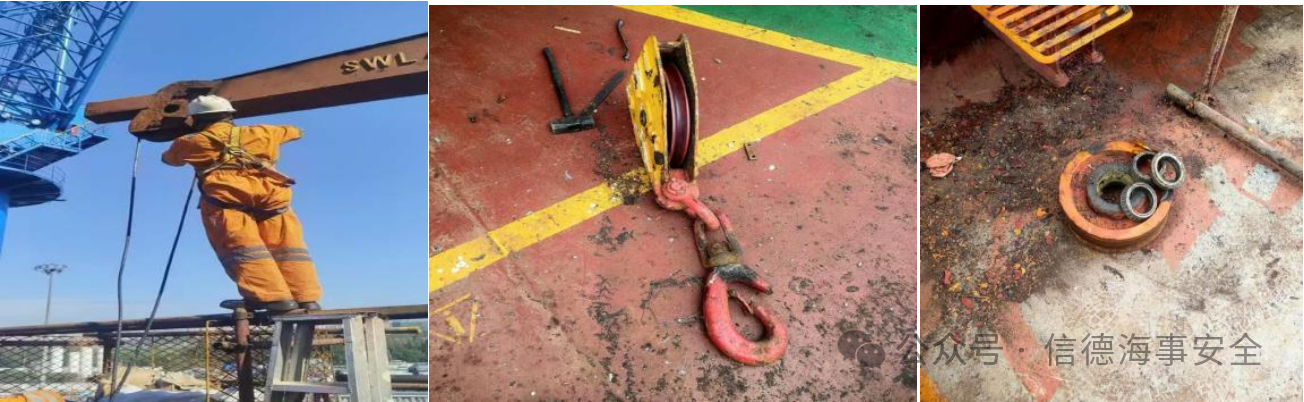

21.救生艇 救助艇

① 钢丝是否需要换新有没有备件

② 滑轮需不需要换新有没有备件

③ 固定滑轮的位置是否腐蚀边薄需要铜匠换新

④ 线管需不需要维修有没有备件

⑤ 登程梯需不需要换新

⑥ 电池有没有备件

22.舷梯 引水梯铝梯

① 钢丝是否需要换新有没有备件

② 滑轮需不需要换新有没有备件

③ 线管需不需要维修有没有备件

④ 检查铝梯的状态,以及船厂需要维修的项目

⑤ 角度指示器

⑥ 码克

23.锚机 缆机

① 测试break holding capacity 的装备

② 刹车带和平头螺丝有没有备件

③ 调整螺丝的支撑是否完好 调整螺丝到刹车片的距离 2-3毫米

④ 刹车带连接件的钢板厚度是否过度锈蚀

⑤ 刹车带位置被船厂拆下后及时敲铲做油漆,很多位置在刹车回装之后就不好处理了,连接位置一定要活络

⑥ 缆车做码克提前准备

24.舱盖检查HATCH COVER

① VENT通风 风暴仓通风特别注意

② BOBBY HATCH 下舱道门有需要铜匠维修的提前打上码克

③ Rubber channel 如果需要换新舱盖橡胶条 提前申请备件和胶水

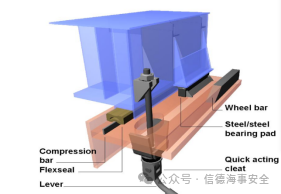

④ Cleat steel washer rubber washer crutch nut

⑤ Wheel 舱盖的轮子

⑥ Support of control box 操纵平台

⑦ Hyd pipe 液压管的状态 需要换新的备件

⑧ Stopper 中间位置的

⑨ Is the packing damaged? 胶条损坏?

⑩ Is the compression bar damaged? 压条损坏?

11 Is the locator problem? 限位的问题?

12 Is the bearing pad problem? 支撑块的问题?

13 Is the cleat problem? 压紧器的问题?

14 Is the drain chocked/broken? 泄水通道堵塞或破裂?

15 Is the structure deformed? 结构变形?

16 舱盖水密实验 可操纵性比较强的是冲水实验

留有记录和照片 这是RIGHTSHIP 的必查项目

General Requirement of Hose Test :

试验水压Pressure: not less than 2kg/cm2

冲水距离Distance: 1-1.5m

25.provision crane and bunker davit

① 钢丝是否需要换新有没有备件

② 滑轮需不需要换新有没有备件

③ 线管需不需要维修提前做好标记

④ 固定电缆的支架

26.提前申请工作服 工作鞋 防尘防毒面罩

船厂可能会换班或者增加很多船员外加机务,海务 额外申请一部分劳保用品备用,压载舱货舱油漆报验需要佩戴防毒面罩

27.压载水舱和干隔舱盖用的螺栓螺帽以及水密垫圈提前申请,因为很多不经常打开的盖子一旦打开垫圈螺栓螺帽可能已经被破坏,建议使用不锈钢材质

① 螺帽 一般M20 根据自己船上的实际情况确认

② 螺栓 一般M20双头螺栓 根据自己船上实际情况确认

③ 密封圈 有圆形有方形

④ 道门盖打开 提前准备护栏

28.油漆的申请

① 甲板保养用

② 淡水仓专用油漆

③ 航行灯用亚光油漆

④ 烟囱用以及机舱用高温油漆

⑤ 离港后机舱清洁 一般会大量使用油漆

⑥ 压载水水舱保养油漆

29.压载舱的检查

① 喇叭吸口 一般船厂在做敲铲油漆时候会用帆布包起来 一定确认压水之前拆掉

② 锌快 要提前买好备件 并且根据图纸确定数量和位置 (我们船18万吨 600多块)

③ 从顶边柜检查通风位置 并提醒保养

④ 透气帽的浮盘

⑤ 透气帽的橡胶圈

⑥ 锁紧螺丝 (一般用2CM 如果滑丝试着用5CM的螺丝就能锁紧 亲自试过)

30.水密门的检查

① 门把手 (确认尺寸 并且把手配套的套管)

② 密封胶条

③ 门上的码克和IMO SYMBOLE

31.CHAIN LOCKER 锚链舱清洁检查 吸水口滤器 测量空的保养

32.透气帽 一些不常开的透气帽不常开 外观完好 容易被忽略 提前检查并且及时保养更换(列举几个位置 但不限于这几个位置)

① COFF TANK

② VOID SPACE

③ ECHO SOUNDER TANK

④ WWTK

⑤ FW TANK

⑥ VENT FOR OIL TANK (要求必须有滤网)

33.甲板空气阀检查并且申请相应备件

34.航行灯信号灯的灯罩打开 检查状态 并且提前申请

35.天线的支撑钢结构检查提前做好标记 高处不容易做的 可以船厂做

36.船厂报验检查工具

① 敲锈锤

② 铲刀

③ 手电

④ 激光笔

在工作中总结出来的内容供船员兄弟参考,众人拾柴火焰高,集思广益一起努力让我们的工作变得相对轻松。祝各位兄弟航安......