Why do an aging fleet and tightening environmental regulations present a golden opportunity for short sea shipping operators? This article looks at three compelling considerations that could give operators the edge when looking for the perfect balance between sustainability and profitability.

For short sea shipping to become more sustainable, there are three key questions that need to be tackled:

1. How do I use less energy to do the same amount of work with my vessel?

2. How do I transform fuel to power more efficiently?

3. What new sources of energy are available to me?

These are the most common questions that Wärtsilä experts hear from customers every day. Let’s dive deeper into each one.

1. How do I use less energy to do the same amount of work with my vessel?

The less energy you need to expend pushing your vessel through the water, the less engine power you need and the lower your fuel consumption and emissions will be. Energy saving technologies (ESTs) are solutions that help you maintain speed while simultaneously reducing fuel consumption.

In the short sea shipping sector, manoeuvrability and speed flexibility are top priorities, with vessels sailing relatively short routes and making frequent port calls. There are several ESTs available today that improve the hydrodynamic and propulsive efficiency of your vessel. For example:

• A properly integrated and optimised propeller and rudder design can reduce fuel consumption and emissions by as much as 9%.

• Replacing the drag of a traditional rudder system with a thrust-generating arrangement that uses foils on either side of the propeller is another way to improve hydrodynamic efficiency. This approach can offer potential fuel savings of 10% while also significantly improving vessel manoeuvrability.

• There are also energy-saving propeller cap solutions that can provide an average saving of 2 to 5% in propulsion energy and emissions. These work by weakening the hub vortex and recovering kinetic energy from the rotating flow aft of the propeller blades.

The question short sea shipping operators are grappling with is how to best to achieve compliance for their specific situation. It’s about balancing CAPEX and OPEX while securing future capabilities that will allow you to comply with tightening regulations. While ESTs increase CAPEX, in the long run they reduce OPEX and improve profit margins by lowering fuel costs. It’s also important to remember that some ESTs come with the added bonus of improved vessel manoeuvrability. This might open up access to new ports with stricter emissions regulations and where vessel movements are more challenging.

Swedish company Furetank is one example of a short sea shipping operator that is incorporating ESTs into its newbuild projects. The company worked with Wärtsilä to install a range of energy-saving solutions, employing Wärtsilä’s OPTI Design approach to achieve optimal propulsion efficiency for their tanker Fure Viten, which left the shipyard in June 2021.

The vessel is powered by a Wärtsilä 34DF dual-fuel main engine and has two Wärtsilä auxiliary engines with a selective catalytic reduction (SCR) system to reduce emissions. A backup battery can take over from the auxiliary engines when sailing through narrow channels, and its highly efficient electric cargo pumps use 15–20% less power than hydraulic pumps and are also much quieter. As well as a shaft generator system, the Fure Viten also has a Wärtsilä High Performance Nozzle to improve thrust and increase propulsion and fuel efficiency as well as a Wärtsilä EnergoPac rudder system to increase manoeuvrability while further reducing fuel consumption.

Sea trials demonstrated that together these technologies reduced CO2 emissions by 55% and NOx by 86% in addition to virtually eliminating SOx and hazardous particulate matter emissions compared to the company’s previous-generation tankers. Critically, they also mean that the Fure Viten has already surpassed the IMO’s 2050 emission targets.

2. How do I transform fuel to power more efficiently?

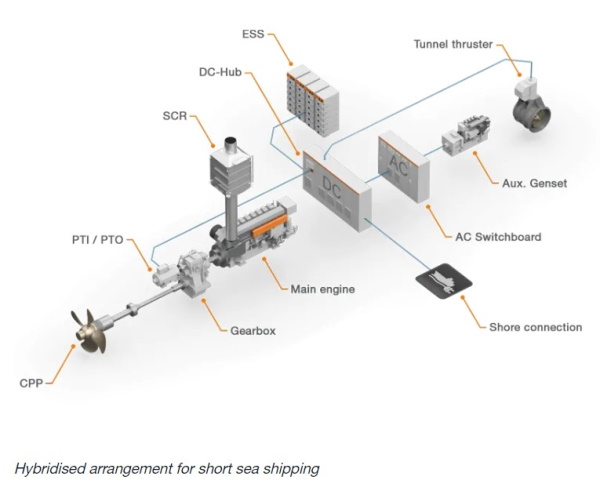

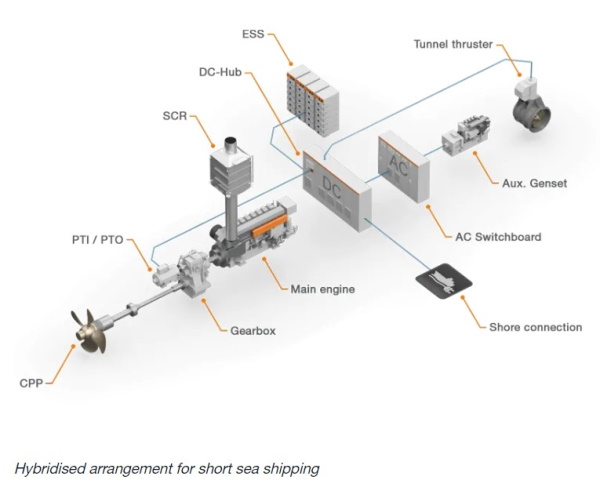

Operators are gradually moving away from the classic short sea shipping setup with a single main engine powering a fixed pitch propeller (FPP) and towards hybridised and electrified propulsion solutions. These provide a more sustainable and flexible foundation for the future.

Hybridisation optimises the engine load based on the vessel speed and operating profile. Engines can be run at optimal load, where they are most efficient, and generate the least emissions, while batteries are used to absorb load fluctuations.

In a mechanical hybrid setup with a controllable pitch propeller, gearbox and shaft generator system, the main engine can be decoupled from the CPP so the vessel can operate solely on battery power when entering and exiting port, eliminating emissions entirely.

In a hybrid electric concept multiple gensets provide propulsion and auxiliary power needs through a common electrical distribution system. Propulsion is provided by electric motors driving a FPP, enabling a highly flexible drive system.

In today’s hybrid propulsion setups, batteries are accompanied by modern engines that are far more efficient than their predecessors.

The core engine power demand of the short sea shipping sector is in the 1–10 MW range. Wärtsilä’s fuel-flexible portfolio includes the Wärtsilä 25. This modular and future-proof solution makes it easier than ever for you to target net-zero by allowing you to transition to greener future fuels simply by replacing selected engine components, which significantly shortens the overhaul time and reduces complexity.

One example of a short sea shipping operator that is using hybrid propulsion to reduce fuel costs and decrease emissions is Misje Eco Bulk, part of the Norway-based Misje Rederi group. In 2020 the company commissioned three 5,000 dwt bulk carriers with a fully integrated Wärtsilä hybrid solution. The solution includes a battery-based energy storage system that provides emission-free power for port movements and cargo operations by eliminating the need to run the engines. The first of these vessels, the Misje Vita, was delivered in autumn 2022.

3. What new sources of energy are available to me?

Tapping into new, greener energy sources can give your short sea shipping operations a big sustainability and efficiency boost. For example, the ability to plug into shore power when in port eliminates the need to use auxiliary engines to cover your vessel’s hotel load. For some vessels, consistent use of shore power can cut emissions and fuel costs by as much as 10% as well as reduce OPEX. The sustainability advantages are even greater when the power is generated from renewable sources like wind or hydro.

Many ports are now investing in shore power infrastructure, and it will gradually become mandatory for vessels to use it. And with the Carbon Intensity Indicator (CII) regulations now in force, decarbonising your port operations with shore power can have a positive influence on your vessel’s CII rating. This is because the rating is based on grams of CO2 emitted per cargo-carrying capacity per nautical miles travelled. Emitting CO2 in port while the vessel is not moving is particularly bad for your CII rating as it is not being offset by any miles travelled.

In terms of fuel as an energy source, more climate-friendly future fuels like LNG, methanol, biodiesel and ammonia are on everyone’s radar. In the short sea shipping segment several operators are eyeing up methanol as a viable option. Methanol is clean burning, cheap to produce, widely available and has the potential to be 100% renewable. Converting to methanol as a marine fuel is a relatively straightforward process if you’re already running on conventional liquid marine fuels.

SAL Heavy Lift GmbH, a German heavy lift and project cargo specialist, is building four new heavy lift vessels with a hybrid propulsion system. The system, which will include methanol-capable Wärtsilä 32 main engines, will minimise the vessels’ CO2 emissions.

Operators who are already using LNG as fuel are looking at ammonia with increasing interest. Ammonia is currently the most viable zero-carbon fuel because of its well-established supply chain and the level of readiness of engine technology. The Wärtsilä 25 is the first engine designed from the start to use ammonia as fuel. The company is also offering dedicated fuel storage and supply solutions and customised exhaust aftertreatment devices for operators who want to make the switch.

Handpicked related content: Weighing up the pros and cons of adopting ammonia? Ammonia – Fuel for thought in our deep-dive Q&A provides the answers to the top questions about this promising future marine fuel.

So the short sea shipping sector is all set to sail towards new horizons, with plenty of options on offer to save fuel and cut emissions. New energy saving devices, propulsion concepts and energy sources can provide a solid base for a more sustainable future for the segment.

The answers to the questions in this article are based on discussions with two of Wärtsilä’s leading experts in the field: Leonardo Ferrero, Team Leader, System Development & Design and Lilli Chi, General Manager, Global New Build Sales Programme.

Source: Wartsila

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  BIMCO Shipping Number of the Week: Bulker newbuildi

BIMCO Shipping Number of the Week: Bulker newbuildi  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar