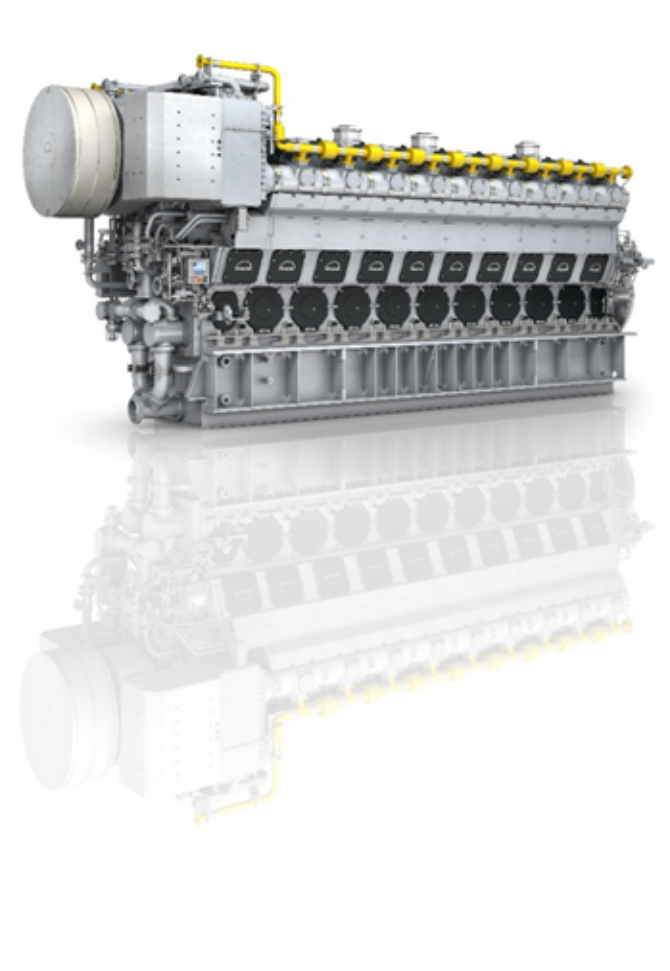

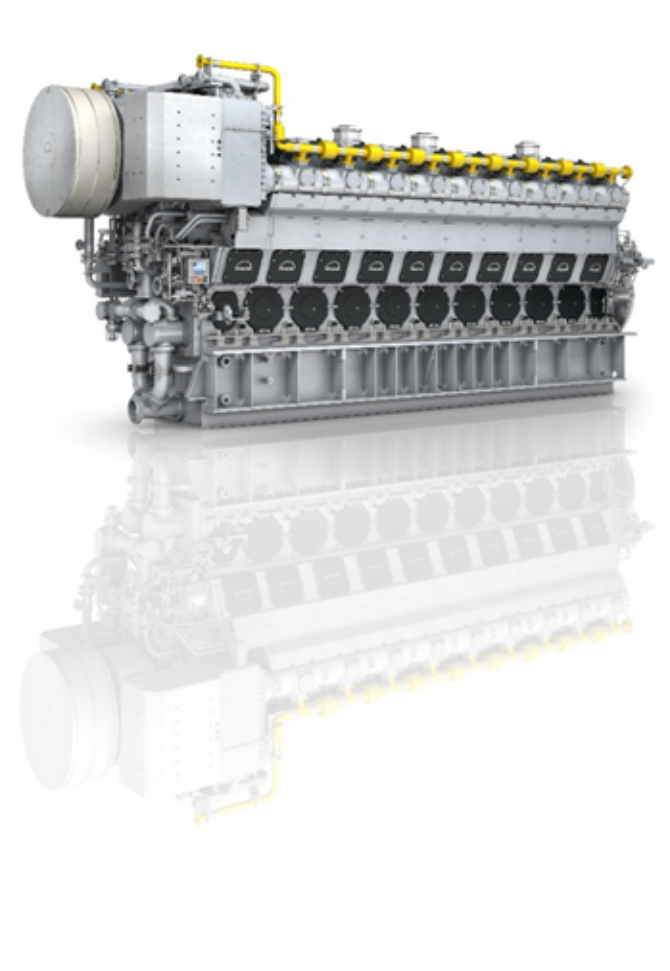

MAN 51/60DF engine

To combat the effects of these inherently unavoidable operating characteristics, MAN sees three promising routes to further limit methane-slip. First, ongoing improvements to internal engine design and electronic controls aim to further increase fuel efficiency and thus the completeness of combustion, improving both methane slip and CO2 emissions. Second, newly developed aftertreatment solutions, namely oxidation catalysts, will enable the reduction of methane-slip by up to 70 %. Third, MAN engineers are evaluating the use of direct gas injection, as used on MAN’s two-stroke DF engines, onfour-stroke DF engines, giving the potential to reduce methane-slip by a value greater than 90 %.

In terms of internal engine design, the methane slip countermeasures devised and under investigation at MAN involve all the major aspects: control of engine operation; combustion processes and their control; basic engine architecture. As they mature, measures are being rigorously applied in both new and existing four-stroke DF engines i.e. the 49/60, 51/60 and 35/44DF and those diesel engines being retrofitted by the MAN PrimeServ after-sales department to run on LNG, such as 48/60 to 51/60 DF conversions.

One important line of attack centres the reduction in the overlap of inlet and exhaust valve openings and the timing of gas admission. “Valve overlap creates an unavoidable period during the inlet stroke of a four-stroke engine when both inlet and exhaust valves are open in order to ‘scavenge’ the cylinder to replace exhaust gases with the charge air or air/fuel mixture. In Otto gas operation, minimising this overlap reduces the time in which air/gas mixture can reach the exhaust port, while close control of the timing and duration of gas admission from electrically-controlled valves in the inlet ports precisely limits the time that gas can enter the cylinder during exhaust valve opening,” Stiesch notes.

In terms of engine architecture, a successful approach is the reduction of crevice volumes in the combustion chamber – i.e.areas where pockets of unburnt gas can be trapped that cannot be reached by the “torches” of progressing combustion. One example is the top land of the piston – the area above the top piston ring on the piston crown. Raising the position of the piston ring reduces the height of the top land, and hence also the crevice volumewhile increasing the rate of combustion efficiency - the accepted metric for completeness of combustion.

In an additionaladvanced approach, MAN has addressed the optimisation of methane conversion using ignition-controlled combustion and the inclusion of combustion pressure sensors in the cylinder to enable cylinderpressure monitoring and cylinder-pressure-based combustion control. The benefits of cylinder cut-off in part load operation are also being utilised.

“As well as abating methane slip, these improvements in the combustion processes of MAN’s four-stroke DF gas engines are leading to considerable improvements in fuel efficiency and hence improved CO2 emissions.” Stiesch remarks. “To date a reduction in specific fuel consumption of around 3 to 3.5 g/kWh has been attained and further potential is anticipated via fine-tuning.”

Turning to aftertreatment, while an oxidation catalyst (“oxicat”) is not an option for two-stroke engines because of low exhaust gas temperatures, it is a well-established technology for removing unburnt hydrocarbons and carbon monoxide from four-stroke engine exhaust gases. The exhaust gas temperatures from MAN’s four-stroke SI and DF engines are in a range that supports the oxidation of methane. “We started developing oxicats as a countermeasure to methane slip in 2017, and we’ve made great progress,” Stiesch confirms. “In the laboratory we have achieved our 70% methane slip reduction target and the first pilot installation aboard ship in commercial operation will start in 2023. We anticipate this technology will be available as a commercial solution for methane slip reductionaround 2025.

“As stated, in the last ten years we have already been able to halve methane slip from our four-stroke gas engines and we are confident that we can achieve at least another 20 % by further improving the combustion process.Furthermore, Otto-cycle gas combustion is characterized by a natural trade-off between methane slip and NOx emissions. For engines equipped with a Selective Catalytic Reduction (SCR) catalyst for NOx abatement, this trade-off can be used to tune the combustion process towards lower methane slip and slightly higher NOx, which can be easily reduced again by the SCR.This is fully proven technology and available today.” Stiesch states.

Methane emissions in gas mode – comparison of different engine types

Finally, there is the possibility of applying a version of the direct gas injection technology used on MAN’s ME-GI two-stroke DFgas engines on its four-stroke DF engines, converting them from the Otto to the Diesel combustion process. It is estimated that it would enable a further reduction in methane-slip estimated at greater than 90%. “However, under the current framework and boundary conditions this is not yet considered a cost-competitive solution for four-stroke engines, and MAN’s emphasis remains on enhancing Otto combustion technology,” Stiesch concludes.

Clearly, MAN is making considerable investments to provide the shipping industry with the low noxious emission, low GHG emission gas engines it needs. For his part, moving from the technical to the political and undoubtedly speaking for makers as a whole, Stiesch would like to see a more stable regulatory framework as development costs accumulate. “Stakeholders on both sides, users and makers, now need to create more specific regulations and see that they are implemented globally and in a coordinated way. Shipping is an international industry with competition between all countries and regions. Regulations should be ambitious but harmonized globally to ensure a level playing field. The International Maritime Organization needs to act in this way.”

Dual-fuel engine technology:

The two- and four-stroke dual-fuel gas engines enabling the shift from fossil fuels (natural gas) to new synthetic zero-carbon and net zero carbon fuels were first used in marine propulsion in LNG carriers.

The first were four-stroke units operating on the Otto combustion process, driving generator sets which supplied both the propulsion motors and other consumers.

The advantage of dual-fuel engines is that they burn boil-off gas from the cargo or can switch to 100% liquid fuel operation with low or no LNG in the tanks.

Source: Jonathan Walker, Freelance Engine Journalist

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  BIMCO Shipping Number of the Week: Bulker newbuildi

BIMCO Shipping Number of the Week: Bulker newbuildi  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar