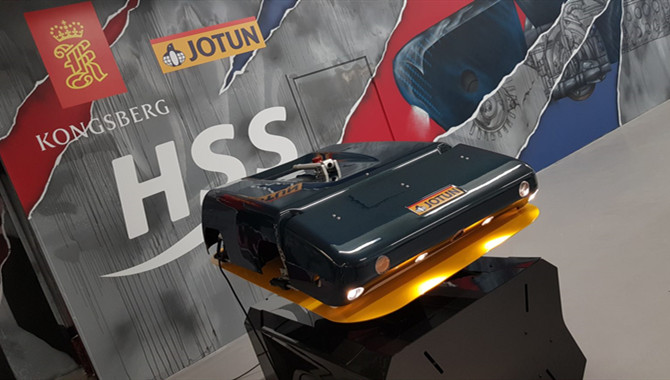

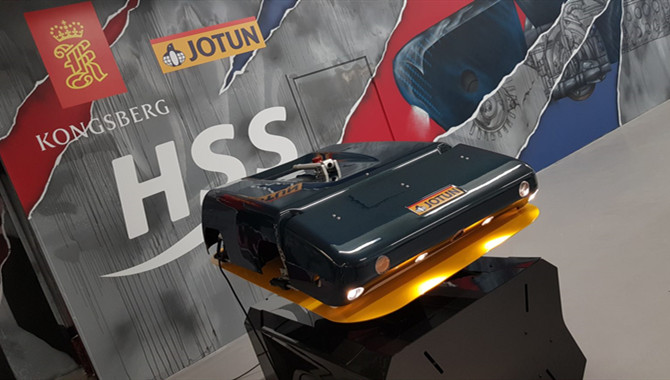

Jotun and Kongsberg Maritime have jointly developed a remotely operated robotic hull cleaning system, which the partners claim could cut CO2 emissions by 12.5% annually on a typical vessel through proactive bio-fouling control.

HullSkater can inspect a 10,000m2 hull in approximately two hours. A permanent fixture on the ship, it would be kept ready to clean fouling from the hull at any time, which causes increased drag if left to accumulate and leads to extra fuel consumption and emissions.

Kongsberg Maritime has worked with Jotun as a partner on the HullSkater project since 2015, contributing to development of systems like remote control, Cloud-based data storage, battery technology, acoustics and composite materials.

Kongsberg will be responsible for the industrialisation and manufacturing of HullSkater going forward, which will take place at a new facility located close to its Sensors & Robotics campus in Horten, Norway.

“Kongsberg Maritime’s expertise in subsea robotics, remote communications and data management, allied with their dedication to sustainability, makes them a perfect fit to partner with us in the development of HullSkater,” said Alfie Ong, Vice President, Jotun Marine Coatings.

“Together, we have devised a truly innovative solution, which we believe will revolutionise the shipping industry, moving away from traditional, reactive methods of managing fouling to a proactive approach which will ensure that vessels are always operating efficiently and sustainably.”

Source:Smart Maritime Network

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

admin@xindemarine.com

Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  BIMCO Shipping Number of the Week: Bulker newbuildi

BIMCO Shipping Number of the Week: Bulker newbuildi  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar