Hundreds of wind-power engineers and workers have kept working at sea during the annual National Day holiday for the construction of China's farthest offshore wind farm in the Yellow Sea.

He Qingdong, an engineer at Jiangsu Offshore Wind Power Company of the State Power Investment Corporation (SPIC), arrived at a port in Dafeng District of east China's Jiangsu Province in the early morning with his colleagues, before heading to the construction site 44 kilometers away at sea.

While other people are happily spending the National Day holiday, the engineers and workers have to speed up the construction when the weather was fine, as they are behind schedule due to interruption of terrible weather conditions in the summer.

"So far this year, our country has experienced many typhoons, four in July and six in August. So we only had five days for construction in August, and less than nine days in September," said He.

He is responsible for the construction of the third phase of the SPIC Dafeng offshore wind power project. The construction has come to a key stage. However, the staff encountered an unexpected problem -- the size of the new vanes for the wind plant was compatible with that of the lifting facility, which made the staff be afraid of possible risks brought about by the traditional installing method.

The construction of offshore projects depends heavily on the weather. He and his colleagues are worried that the project would have to be suspended at the current phase if the wind became stronger.

"The wind speed may exceed 10 meters per second at 17:00. And if it exceeds 10 meters per second, we will not be able to hoist the vanes. If [the lifting] doesn't complete by 17:00 or it is lifted just halfway, it's will be terrible," said He.

After consultations time and again, He and his colleagues formulated a new lifting plan to largely reduce the risk by adjusting the angle of the vane to increase the space of operating the lifting facility in the air. However, to lift the over 60-meter and eight-ton vane to a height of 90 meters still made everyone nervous.

After two hours, the vane was lifted to a place 10 meters away from the plant, which was then followed by the most important part of the work -- to dock the 124 big bolts accurately with the plant. Finally, six hours later, the first vane was successfully installed.

After a sigh with relief, the staff soon began to install the remaining two vanes. Their work continued even at night, since the window phase for offshore constructions is very precious. In racing against time, they always had to work 24 hours a day if conditions permitted.

In addition, they also needed to overcome natural disadvantage as well as physical discomfort. Over the past year since the project started, more than 400 construction workers have been working here continuously, finishing the construction of wind power plants one after another.

"Such a large offshore wind power plant is constructed by our hands -- from nothing at the beginning to a completed plant which then generates power. It's like my child who is growing step by step. I feel very proud," said He.

The whole project is scheduled to be completed by the end of November. It will be able to generate 870 million kwh of electricity a year, which meets the annual demand of nearly one million families for electric power supply. Together with the first and second phases, this project will become the largest offshore wind array in the world.

Sources:cctvplus

Please Contact Us at:

admin@xindemarine.com

WOODSIDE AND CHINA RESOURCES AGREE LONG-TERM LNG SU

WOODSIDE AND CHINA RESOURCES AGREE LONG-TERM LNG SU  Shanghai Yangshan Port Bunkered Two LNG Powered Con

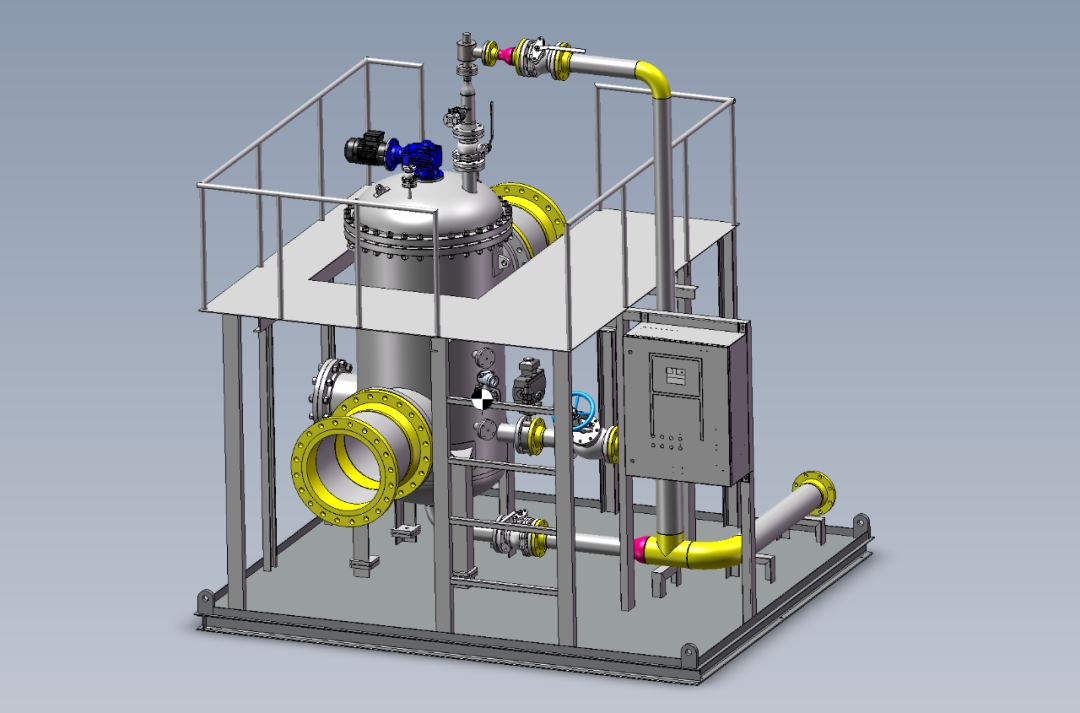

Shanghai Yangshan Port Bunkered Two LNG Powered Con  Headway successfully delivers filtration skid solut

Headway successfully delivers filtration skid solut  Celebrating the Launch of “Green Energy Pearl” –

Celebrating the Launch of “Green Energy Pearl” –  PIL and SSES complete the inaugural LNG bunkering o

PIL and SSES complete the inaugural LNG bunkering o  BW LNG secures e-procurement deal with Procureship

BW LNG secures e-procurement deal with Procureship